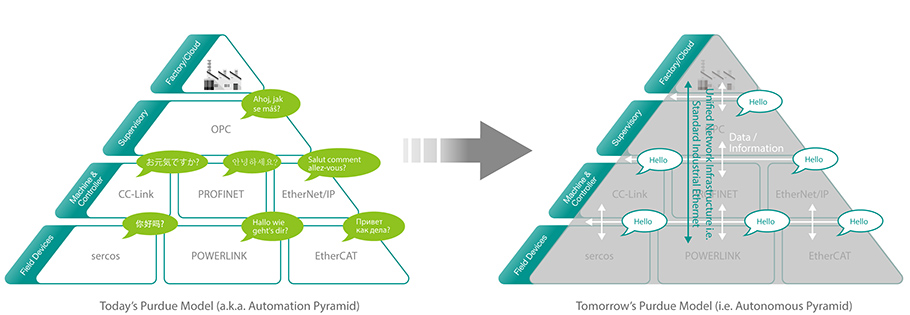

Establishing an intelligent factory poses challenges. Previously, factories used to create their own intricate network structure to optimize the performance of workstations, production lines, and control centers for various applications and functions.

As the push towards Industry 4.0 emphasizes enhanced production capabilities and reduced costs, there is also a shift towards mass customization in manufacturing. This approach relies on connecting all devices in the factory, merging IT and OT networks to collect real-time data from raw materials through production to customer delivery, enabling factories to enhance their production strategies.

To transition from traditional network architecture to smart factories, system integrators face hurdles like technical feasibility, additional construction, and increased maintenance costs.

The automation industry has long anticipated a consolidated network to address contemporary factory challenges. Time-Sensitive Networking (TSN) technology, built on standard Ethernet, offers network-wide time synchronization, reduced latency, increased reliability, and streamlined management supporting industrial Ethernet protocols. TSN resolves complexities of IT and OT convergence, bridging automation silos to realize the Industry 4.0 vision.

The ODVA, an association of leading industrial automation manufacturers, highlights that the TSN standard enables sending time-critical data via industrial Ethernet networks, accommodating the surge in data traffic due to IT and OT convergence.

While TSN technology has been under development, companies keen on smart factory deployment await its practical benefits. System integrators suggest TSN technology is yet to be effectively implemented and anticipate its commercialization and a comprehensive TSN ecosystem.

Nevertheless, the pivotal question stands: Is TSN primed for smart factory implementation?

We identify three critical prerequisites for successful TSN integration.

Prerequisite 1: Backing Industrial Ethernet Protocols Over TSN

Industrial communication technology is crucial for factory operations, with industrial Ethernet protocols playing a significant role in the OT network. Different organizations devise tailored protocols, leading to disparate systems that struggle to communicate and collaborate.

With TSN technology’s introduction, major industrial Ethernet protocol bodies have started formulating standards for TSN-compatible protocols. This allows users across protocol ecosystems to leverage cutting-edge TSN technology.

For instance, in 2018, the CLPA finalized the “CC-Link IE TSN” spec based on TSN, showcasing benefits in varied applications like automotive paint shops and semiconductor processing tools. The CLPA has over 300 members, with several manufacturers releasing CC-Link IE TSN compliant products.

The PI organization introduced TSN support for PROFINET in 2019, advancing TSN technology and ecosystem development.

The OPC Foundation’s “OPC UA FLC initiative” aims to establish real-time communication protocols based on TSN. Although ongoing, substantial progress was showcased at the 2019 Hannover Messe.

OPC UA FLC initiative major contributors

Source: https://opcfoundation.org/wp-content/uploads/2020/10/OPCF-FLC.pdf

EtherNet/IP, developed by ODVA, is working on incorporating TSN into its standard, showing progress in updates to support TSN.

These pivotal industrial Ethernet protocols are evolving to embrace the TSN standard. Although at different stages, they are no longer mere theoretical concepts. Moreover, some manufacturers have rolled out TSN-capable products compatible with these protocols.

Prerequisite 2: Preparedness of TSN Solutions

Post-industrial Ethernet protocol advancements, the readiness of TSN solutions becomes a crucial barrier. Automation devices, systems, and production lines in intelligent factories necessitate TSN support from software and hardware for practical implementation.

Development kits, stacks, and boards can aid device manufacturers in creating TSN-ready applications and products. Automation equipment like controllers, switches, HMIs, inverters, and IOs must support TSN functionalities to assist in building future automation systems and networks.

Additionally, there’s a notable rise in the number of managed devicesand gathered information in intelligent factories. To assist integration experts in cutting down on overall deployment and upkeep expenses, the software management tool for centralized control of TSN equipment is also a crucial component of the complete solution. This can aid field technicians in simplifying intricate application requirements and saving a substantial amount of time during the configuration of TSN devices.

When examining the entire TSN ecosystem, following the inception of the Smart Production Solutions (SPS) in Germany back in 2016, various chip manufacturers, development board producers, equipment suppliers, and software kit developers have progressively been introducing TSN-related products. The release of products by the major automation companies in recent years clearly indicates the swift maturation of TSN-based solutions.

Requirement 3: Multivendor Interoperability

While TSN comprises several well-known Ethernet standards, issues of compatibility between devices from different manufacturers are unavoidable. In response, four significant TSN interoperability testing platforms have been set up worldwide, including the Industrial Internet Consortium (IIC), Labs Network Industrie 4.0 (LNI 4.0), Alliance of Industrial Internet (AII), and the Edge Computing Consortium (ECC). These platforms enable device manufacturers to collaborate to guarantee the interoperability and seamless integration of TSN technology among devices.

During the 2019 Hannover Messe trade fair in Germany, the Industrial Internet Consortium (IIC) showcased its joint demonstration. This not only illustrated the dedication of numerous manufacturers to providing TSN solutions but also served as a tangible means of reassuring integration experts and users.

The IIC joint demo at the 2019 Hannover Messe

TSN Is Ready

Through the combined efforts of various TSN suppliers, the essential elements for establishing a TSN ecosystem are gradually being implemented, with significant progress already achieved.

In recent years, numerous practical TSN application demonstrations have been presented at automation exhibitions worldwide. These exhibitions serve as evidence of the commitment of standard organizations and manufacturers to support the advancement of TSN technology. Moxa, as an active contributor from the initial stages of defining the TSN standard, has collaborated with industry frontrunners to propel the development of the TSN ecosystem.

In November 2019, Moxa, alongside Mitsubishi Electric, B&R, and Acontis, unveiled the “TSN: unified network infrastructure” at the Smart Production Solutions (SPS) event in Nuremberg, Germany. Utilizing a TSN integrated network architecture, two major industrial Ethernet protocols, CC-Link IE TSN and OPC UA, operated over TSN. This showcase fused motion control, image streaming, data acquisition, and other applications to exhibit the tangible implementation of TSN with multiple products. (For more information see TSN—The Future Is Now)

2019 SPS TSN demo kit display

At the Taipei International Industrial Automation Exhibition in August 2020, Moxa was invited by CLPA to showcase the TSN unified network architecture, demonstrating the operation of Moxa’s CC-Link IE TSN-certified switches for the first time.

2020 Taipei International Industrial Automation Exhibition demo kit display

In the past, the industry viewed the TSN standards and technology as still being in the early phases of development. Support for industrial Ethernet protocols, solution readiness, and interoperability are the three main factors hindering the implementation of TSN technology. Based on recent advancements, we are aware that these barriers are gradually diminishing.

TSN is no longer just a concept. The introduction of TSN-compatible industrial Ethernet protocols and comprehensive TSN solutions designed by device manufacturers all contribute to the establishment of a genuine TSN ecosystem, set to become the foundation of the future Industrial Internet of Things (IIoT) era.

For further details on TSN, download our white paper or visit our TSN website.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024