In trade ports, a significant amount of containers get transported to and from container ships on a daily basis. The quicker the port operator loads and unloads the cargo containers, the more vessels the harbor can accommodate. The higher the number of ships and cargo the harbor deals with, the greater the revenue for the port operator. One of the most crucial systems utilized to achieve automated port handling is the crane optical character recognition (OCR) system. This system is set up on the port gantry cranes, effectively substituting human eyes with digital “eyes” that can instantly authenticate serial numbers on swiftly moving cargo containers and verify the integrity of each container managed. Apart from averting mishaps during cargo transportation, OCR systems ensure the safety of personnel from perilous work locations while enhancing the efficiency of the cargo handling process. Nonetheless, in order to realize these advantages, system integrators of port automation systems must meet demanding prerequisites for constructing a dependable crane OCR system.

Three Prerequisites for Crane OCR Systems

Crane OCR systems for trade ports must meet the following three conditions:

1. Industrial-level Dependability

All OCR systems for automated container cranes operate outdoors and must endure a broad array of severe weather conditions. Even warm water ports in moderate climates will expose any device used in the OCR system to the detrimental effects of high moisture levels and corrosive salinity from sea water. Consequently, all network equipment needs to be adequately sturdy with industrial-grade design and high MTBF.

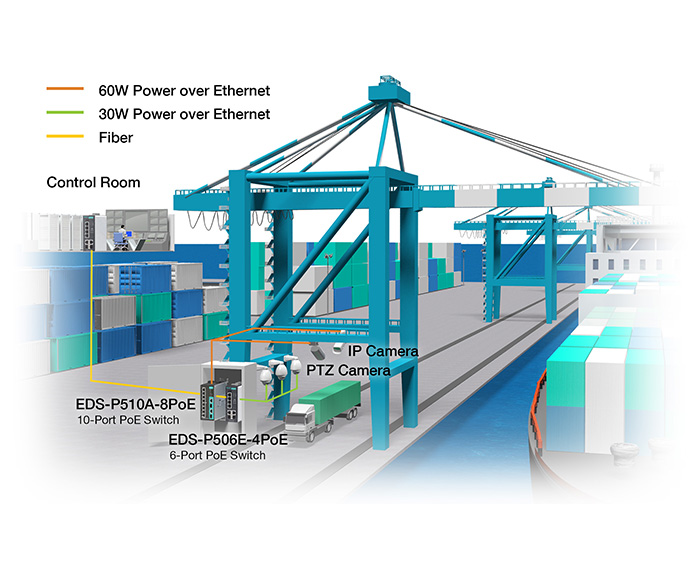

2. More than a new set of eyes

The principal aim of an OCR system is to aid operators in perceiving and tracking what can easily be overlooked by human eyes. Consequently, applications often deploy PTZ cameras to provide remote monitoring personnel with perspectives from alternate angles, as well as the capability to zoom in and out for different outlooks. Nonetheless, the majority of PTZ cameras necessitate 60 W of power input when deployed in outdoor industrial applications. In settings where port cabling is complex, system integrators generally utilize high-power PoE switches to supply power to the cameras, as regular PoE switches typically only have power outputs of around 30 W.

3. Analysis and oversight from a distance

Although remote monitoring ensures the safety of individuals from hazardous work environments, the images still need to be transmitted back to the port terminal’s remote control center for further processing and analysis in real time. To avoid any disruptions to operations, system administrators also require a convenient method to manage, monitor, and uphold the network and devices remotely.

A Genuine Crane OCR System Case

A worldwide cargo port operator in the United States requested an exceedingly reliable crane OCR system for their port terminal automation application. Moxa managed to offer a complete range of robust solutions to fulfill all camera requirements and aid the port operator in achieving dependable network data transmissions. By affixing PTZ cameras on the front and rear of each crane, the port operator can capture images of each container’s serial number, and also evaluate the condition of the container doors in real time. Moxa’s solutions encompass the EDS-P506E-4PoE managed switch, which is furnished with 4 PoE+ ports with high power output of up to 60 W per port for PTZ cameras. For cameras that do not necessitate as much power, Moxa also furnishes the EDS-P510A-8PoE, a cost-effective 8-port IEEE 802.3at compliant PoE switch.

All the images are also instantaneously transmitted to the port operator’s remote control center for further data analysis via the Moxa PoE switches. To assure reliable data transmission, both the EDS-P506E-4PoE and EDS-P510A-8PoE switches provide Moxa Turbo Ring redundancy for swift network recovery in under 20 milliseconds. Furthermore, system administrators can also leverage Moxa MXstudio network management software to remotely visualize and manage the network of crane OCR systems. Besides being part of the network itself, both of these Moxa PoE switches encompass a built-in “Smart PoE” feature to support remote-controlled cameras and powered device (PD) management, including PD status monitoring, remote PoE port power cycling, and PoE port power cycle scheduling.

In brief, the solutions enabled the cargo port operator to realize the following benefits:

- Enhance productivity and efficiency for the crane operation

- Ensure network dependability and availability with network redundancy technologies

- Visualize the remote crane OCR system status anytime, anywhere

- Lessen future maintenance effort

To discover more about how Moxa high-power PoE solutions facilitate dependable networks for surveillance systems, download our application notes.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024