CNC machines are crucial in numerous manufacturing applications, shaping various materials like metal and plastic into desired forms. These machines have evolved with advanced technologies, incorporating more axes for precision and improved efficiency. To prevent downtime, it is essential to monitor complex components, operational speed, and machine status attentively.

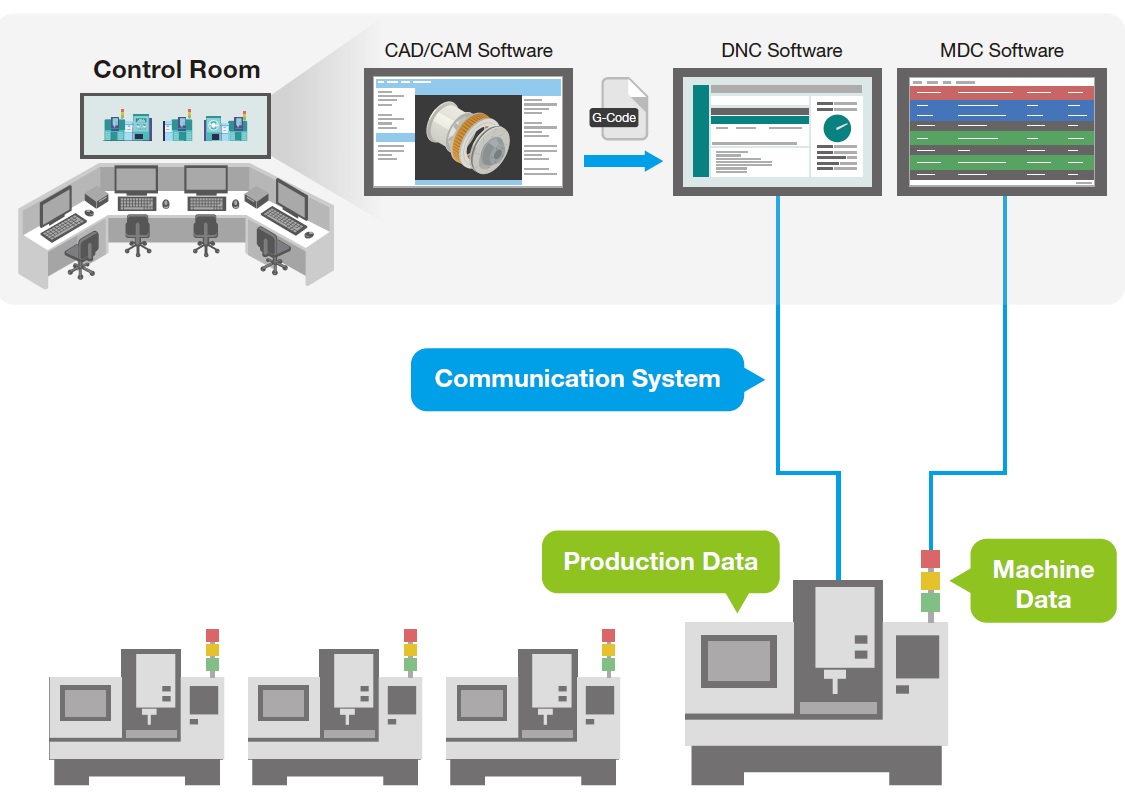

If a CNC machine in a factory is not operating, it results in profit loss. Therefore, the effectiveness of CNC machines significantly impacts the factory’s profitability. Real-time information on CNC machine statuses is crucial for improving productivity. Your machine data collection (MDC) strategy can focus on enabling distributed numerical control (DNC) communication, basic MDC to measure equipment efficiency, and advanced MDC for predictive maintenance.

Effective DNC Communication

Many factory operators still deal with legacy serial CNC machines. To streamline production, DNC software is used to transmit G-code to multiple CNCs over a network, significantly increasing productivity.

Data Collection from Machines

Machinery, being a substantial investment, generates revenue when in operation. Machine monitoring can reduce nonproductive time, boosting utilization rates for improved productivity. Manual data collection is inefficient; MDC software ensures accurate and timely machine information retrieval.

Improving operational efficiency or OEE requires seamless communication between DNC/MDC software and CNC machines. Here are some connectivity recommendations.

Diverse Connectivity Needs

Legacy CNC machines often require multiple interfaces for connectivity with DNC/MDC software. Solutions like serial-to-Ethernet interfaces can update G-code on serial CNC machines, enhancing efficiency and reducing cabling costs with wireless solutions.

Reliable Communication Performance

Reliable data transmission is critical in DNC-to-CNC communications. Slow data transfers due to small memory caches or constraints in serial connections can lead to bottlenecks, affecting production. Connectivity solutions with efficient flow control mechanisms are vital for minimal latency in data transmissions.

Ensuring Cybersecurity

Cybersecurity is increasingly crucial in industrial settings. Protecting CNC applications from cybersecurity threats, especially when connected to the Internet, is vital for uninterrupted operations. Implementing measures like password protection and account management can safeguard sensitive production data.

By enabling online connectivity for CNC machines, operators can swiftly address productivity issues, minimizing downtime and costs. Moxa offers reliable connectivity solutions for machine data collection applications. Access our case studies for more information.

For assistance in selecting networking products for your project, download our E-book to learn about key selection criteria.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024