Seamless Connectivity and Data Transparency in Smart Factories

Smart manufacturing necessitates comprehensive data openness to facilitate the digitization of the entire production and distribution network. Numerous factory proprietors are merging their facility management systems with the intelligent factory infrastructure to attain enhanced controllability and quicker response times, thereby optimizing the overall equipment efficiency. This translates to a significant surge in the quantity of end devices requiring connectivity. Tailored industrial computing solutions catering to the data collection necessities of intelligent factories are closing the divide between the IT and OT realms by providing high-efficiency, dependable, user-friendly solutions. We explore two common applications in facility management and environmental control to grasp the crucial function that computing solutions execute in fostering Industry 4.0 in manufacturing plants and laying the groundwork for a future surrounded by extensive data analysis, self-directing devices, and business insight.

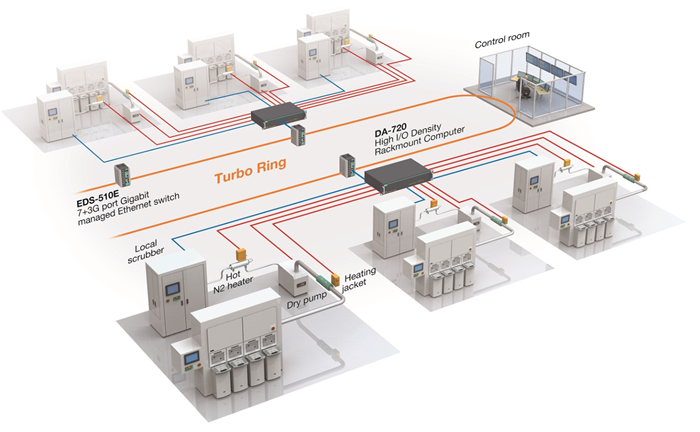

Efficient Device Control in Dry Pump Monitoring Systems

Control mechanisms for devices, such as GIS, dry pump, and local purifier systems, represent pivotal components of a facility management and control structure (FMCS). Typically, there exist hundreds of devices in an FMCS that demand supervision, with a majority of them situated in far-flung regions. The control interface should possess the capability to link with all these devices and assist in optimizing and boosting the overall equipment efficiency (OEE).

Moreover, the system ought to enable protocol conversion amid the different dry pump devices to enable seamless communication for quicker response times. Real-time data collection, storage, and administration facilitate predictive system upkeep and decrease system downtime. Reliable network functionality is indispensable in the harsh settings of a dry pump facility where electrical disturbances are common.

Moxa’s DA-720, a top-notch industrial-grade x86 platform, proves ideal for this scenario:

- Intel® Core™ i7, 2.6 GHz, dual-core CPU or i5, 2.4 GHz, dual-core CPU (Skylake)

- High I/O density with up to 22 Gigabit LAN ports plus 10 serial ports, or 14 Gigabit . LAN ports plus 18 serial ports

- Moxa’s fanless heat dissipation technology

- PRP/HSR support to establish network redundancy for high network availability

- Proactive Monitoring and Smart Recovery support for easy maintenance

- Remote control functionality for managing devices at unmanned sites

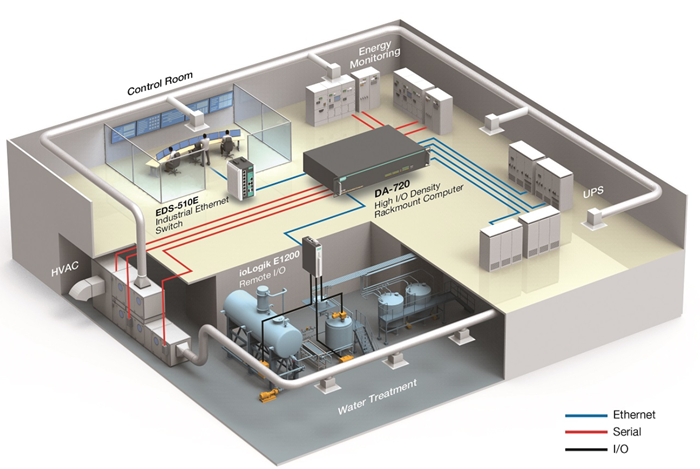

Power and Environmental Monitoring System

Control and monitoring systems for the environment, such as UPS, HVAC, access control, lighting management, and fire alarm systems, are vital components of a facility management and control setup (FMCS). When scrutinizing and evaluating the vast array of assorted data from these systems, it is imperative to pick a reliable, high-performance computing platform optimized for data capture and protocol conversion.

Data collection and computing solutions utilized in FMCS must offer robust system stability and longevity. Remote control functionality for overseeing and handling IIoT devices, particularly those positioned in uninhabited places, is fundamental. Furthermore, the platform should deliver seamless performance amidst the cacophony of an industrial plant environment.

Moxa’s DA-720 rugged computers present a fanless construction for prolonged use, deliver Level-4 EMC protection, and encompass Proactive Monitoring and Smart Recovery features to reduce system downtime. These computers facilitate remote control functions for supervising devices and apparatus located in distant, demanding locales.

To gain deeper insights into the DA-720 computing platform, download the product brochure.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024