Heating, ventilation, and air conditioning (HVAC) systems are crucial for the efficient functioning of both commercial and industrial structures. These systems are responsible for maintaining comfortable temperatures and ensuring good air quality for occupants, while also supporting the necessary climate conditions for goods and products. But how can you ascertain the normal operation of your HVAC setup and confirm that it is functioning optimally to save energy and costs? By utilizing remote monitoring systems, facility managers can visualize the current status of different HVAC units and environmental variables, thereby avoiding potential system breakdowns and optimizing overall performance.

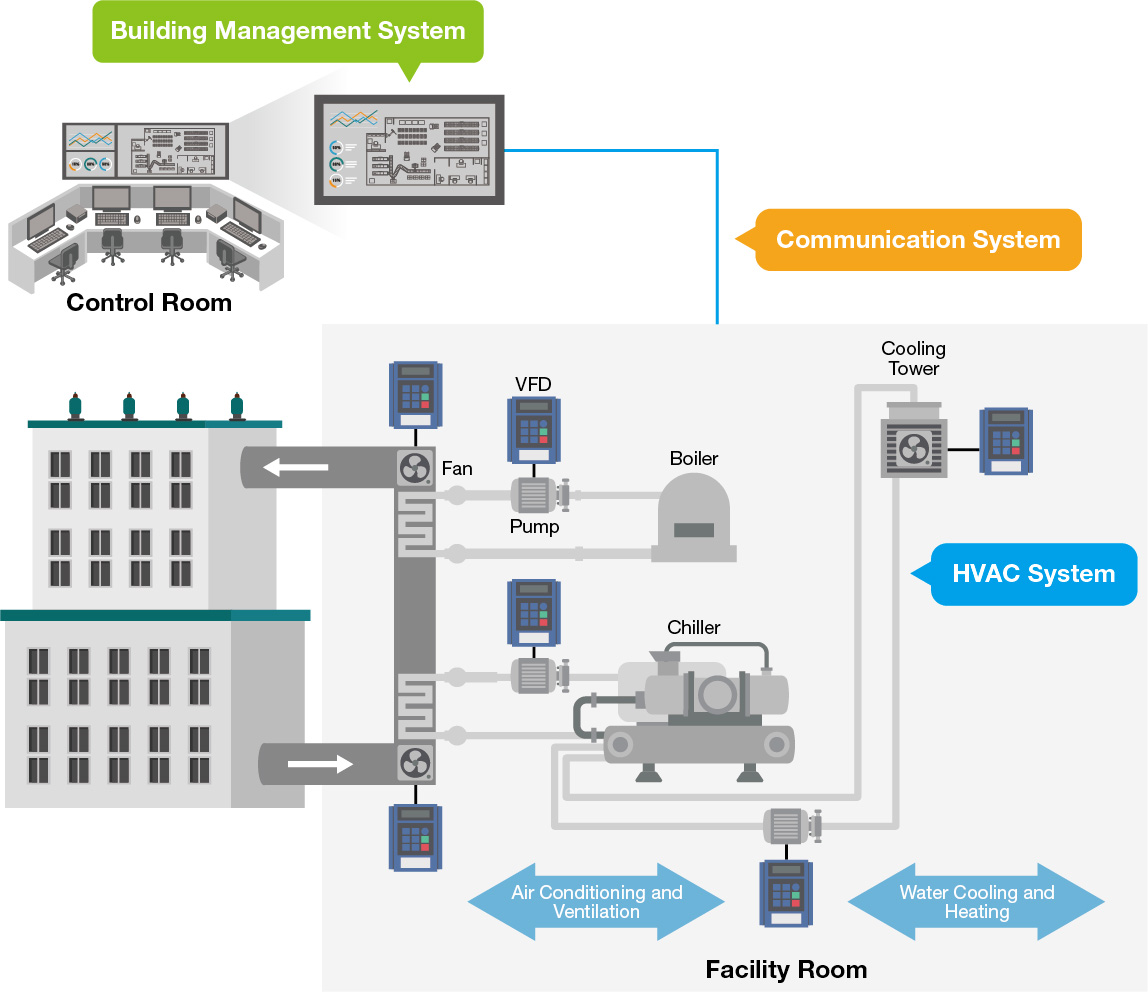

The management of HVAC equipment typically falls under the purview of a building management system (BMS) or building automation system (BAS). A BMS integrates various sub-systems, with the mechanical system being the core component responsible for the physical operations within a building. These operations include functions like cooling, pumping, and ventilation, encompassing numerous mechanical devices. The electrical system, on the other hand, deals with power and electrical equipment, such as transformers, panels, generators, and uninterruptible power supplies (UPS). It is essential to monitor critical sub-systems like boilers, generators, heat pumps, fans, chillers, and pumping units to identify any irregularities and alert building operators for proactive maintenance.

Therefore, establishing connectivity is the initial and most crucial step in developing a remote monitoring system for your HVAC setup. To ensure a hassle-free installation and operation of your connectivity solution, take into account the following aspects:

Seamless Interoperability

The main goal of a connectivity solution is to deliver remote field information to building operators. The selected monitoring devices should be capable of retrieving data from a range of HVAC equipment and sensors that employ diverse protocols like Modbus TCP or BACnet/IP. When equipment lacks a communication interface to output status data, additional hard-wired sensors are needed for capturing equipment readings and environmental conditions. Sensors for environmental monitoring often measure parameters such as CO2 levels, water pressure, airflow, temperature, and humidity. For equipment monitoring, factors like vibration, power failure, and power usage are typically observed in the field. Advanced sensors may come equipped with networking interfaces for direct connectivity to the primary communication backbone. In the absence of such sensors, remote I/O units may be necessary.

Efficient Connectivity Solutions for Simplified Configuration and Troubleshooting

Depending on the scale of the project, an HVAC system might require numerous monitoring devices. The larger the scope of implementation, the more effort is needed for installation and configuration. Wiring considerations are also crucial while planning the monitoring network. Features like Ethernet cascading can significantly enhance installation efficiency.

Configuring monitoring devices individually can be time-consuming without user-friendly tools. Routine maintenance tasks such as configuration backups or device firmware updates can be cumbersome if carried out manually. Hence, when selecting connectivity devices for monitoring your HVAC system, focus on solutions that offer easy-to-use configuration tools and troubleshooting utilities to swiftly identify communication issues and reduce downtime.

Emphasize Cybersecurity Measures

While enabling remote connectivity for all devices provides real-time information convenience, it also exposes systems to additional cybersecurity threats. Prioritize devices that are equipped with essential security features like password protection, secure network protocols, and event data logging. In addition to device-level security, system-wide protections such as firewalls and regular vulnerability assessments are necessary to mitigate potential risks.

With extensive experience in industrial connectivity, Moxa has assisted clients worldwide in establishing reliable communication for remotely monitoring their HVAC systems. Explore our case studies to learn how other businesses leverage Moxa’s solutions in practical scenarios.

Need assistance in selecting connectivity or networking solutions for your project? Access our E-book for insights on the key factors to consider when choosing the right products to meet your requirements.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024