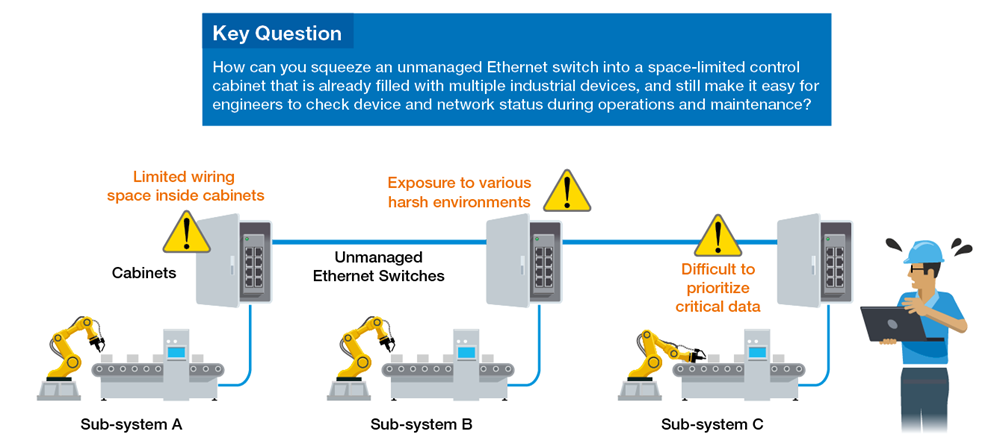

Establishing a restricted quantity of devices within a single framework can be quite challenging. In the case of a solitary automated assembly line, perhaps only one or two Ethernet network nodes are necessary to facilitate connectivity, enabling control center operators to supervise system status and react to incidents. Now, envision the complexity involved in linking an increasing array of devices from various systems to a unified network. Every obstacle is magnified—a daunting truth that confronts industrial automation engineers tasked with merging several automated production lines across diverse facilities. How can you guarantee that all these devices and Ethernet nodes are interconnected and that operators obtain crucial data to sustain uninterrupted operations?

One possible approach is to implement additional managed Ethernet switches, which empower you to oversee your network transmissions and establish correlated parameters in accordance with your requirements. While managed Ethernet switches provide enhanced control and specificity, maintaining multiple managed switches demands considerable time and effort. Furthermore, augmenting the number of manageable network nodes may elevate configuration and upkeep efforts. Consequently, deliberate network planning and design are pivotal to prevent rapid network expansion. Alternatively, integrating unmanaged switches at specific network nodes may optimize overall network efficiency and diminish maintenance endeavors.

Vital Criteria for Selecting Unmanaged Ethernet Switches

In industrial settings, unmanaged Ethernet switches are often perceived merely as network hubs for connecting field data to IP networks. While industrial operations are in progress, operators might overlook the presence of unmanaged Ethernet switches in their networks. However, as more devices link up to generate business insights, operators may feel overwhelmed by unexpected network instability. To meet escalating network demands, unmanaged Ethernet switches necessitate additional functionalities. Here are some significant criteria to aid in determining the most suitable unmanaged switches for your IIoT applications.

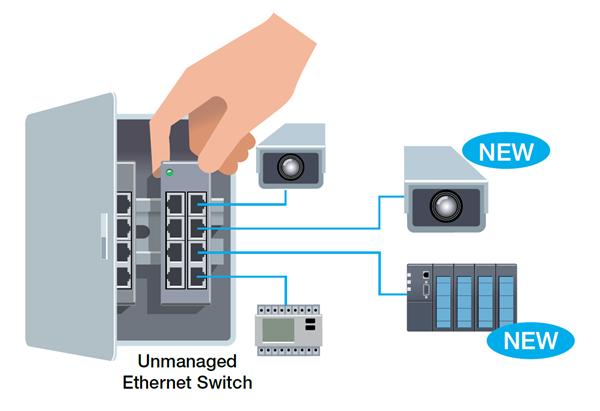

Strategize for Expansion

The fundamental necessity to ensure that your network can accommodate a growing number of interconnected devices is to leverage unmanaged switches with an ample number of ports and sufficient bandwidth to handle high data volumes. Unmanaged switches are typically placed in space-constrained enclosures, so deploying a compact yet high port density solution can also alleviate future expansion concerns. Another pivotal factor is network speed and data transmission range. Nowadays, diverse data types such as video streaming necessitate substantial bandwidth and impact overall transmission speed. Unmanaged switches equipped with Gigabit ports or fiber ports can guarantee ample network speed for data uplinks, both presently and in the future.

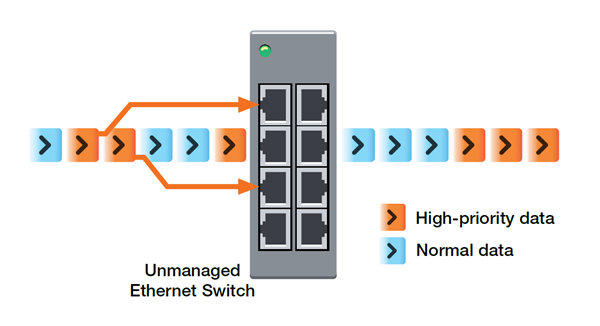

Prioritize Packets at Each Node

Quality of Service (QoS) is a commonplace feature used to ensure that critical data always receives high-priority transmission. Without QoS, critical data may encounter delays during transmission if the network is congested. Although QoS is typically supported by managed switches or specific control equipment like PLC devices, it is seldom found in unmanaged switches. Given the growing demand on network nodes to transmit varied data types from field locations, it is reasonable to include this functionality in unmanaged switches to guarantee the prompt transmission of critical data without the necessity of deploying managed switches at every node, involving additional cost and effort.

While selecting unmanaged switches, confirm whether they incorporate QoS or comparable functions to prioritize critical data processing, ensuring network simplicity and preventing excessive time and effort being spent on managing unnecessary features in managed switches.

Confirm Reliability for Any Environment

Selecting unmanaged switches with industry certifications tailored to your specific application prerequisites is a straightforward method to ensure reliability. While not all industrial applications demand certifications, it’s vital to be mindful of two commonly encountered environmental circumstances: extreme temperatures and substantial electromagnetic interference. Unmanaged switches featuring broad operating temperatures and redundant power inputs can maintain network operation under adverse conditions. In case of emergencies such as power failures or port malfunctions during operation, unmanaged switches should be capable of issuing alerts to operators for prompt responses.

Utilizing the aforementioned three criteria to evaluate your options can guide you in identifying the suitable unmanaged switches for your industrial applications. To cater to the expanding requirements of industrial networks, Moxa has developed a novel range of industrial unmanaged Ethernet switches—the EDS-2000-EL Series and EDS-2000-ML Series—that deliver a compact footprint, reliability, easy deployment, and adaptability for various industrial applications. If you wish to delve deeper into industrial networking, download our E-book.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024