Throughout the years, serial connectivity has maintained its reputation for ensuring dependable connections in numerous industrial settings. Despite the growing popularity of Ethernet communication, many older devices in factories still heavily rely on serial interfaces. As industrial managers increasingly understand the benefits of integrating operational technology (OT) with information technology (IT) to boost efficiency, it falls upon field engineers and system integrators to tackle the challenges of merging legacy systems with newer ones. Luckily, solutions like serial device servers play a crucial role in bridging the communication gap between traditional serial devices and modern Ethernet-based systems. However, with serial and Ethernet transmissions being fundamentally different, concerns may arise regarding the stability of TCP/IP networks and the read/write performance during the shift from a serial to Ethernet network.

Our NPort serial device servers are equipped with a feature called Real COM driver, which establishes a virtual COM port on the host computer to link the IP port on the network, enabling serial devices at the edge to communicate with the host computer seamlessly as if they were physically connected by serial cables, without the need to modify any serial software applications. Furthermore, the Real COM driver offers a comprehensive range of advanced functions to ensure that the virtual serial port operates as closely as possible to a native serial port.

This article will delve into how you can efficiently address the challenges of serial-to-Ethernet communication using the Real COM driver in two common factory applications: CNC machines and Automated Guided Vehicles (AGV) monitoring.

Case Study 1: CNC Machine Monitoring

Traditional CNC machines typically utilize RS-232 communication protocols. To enhance the productivity of CNC machines, real-time data retrieval plays a crucial role, allowing immediate responses to mitigate downtime or timely switching of manufacturing programs. This necessitates the implementation of remote monitoring applications to oversee and control CNC machines from the central control center. Implementing serial device servers to bridge the communication gap between serial-based CNC machines and Ethernet-based systems in the control center is essential. However, the transition of data between differing communication methods may lead to uncertainties regarding network reliability. Moreover, converting serial data over Ethernet networks can impact the efficiency of data transmission.

Benefits of NPort Implementation

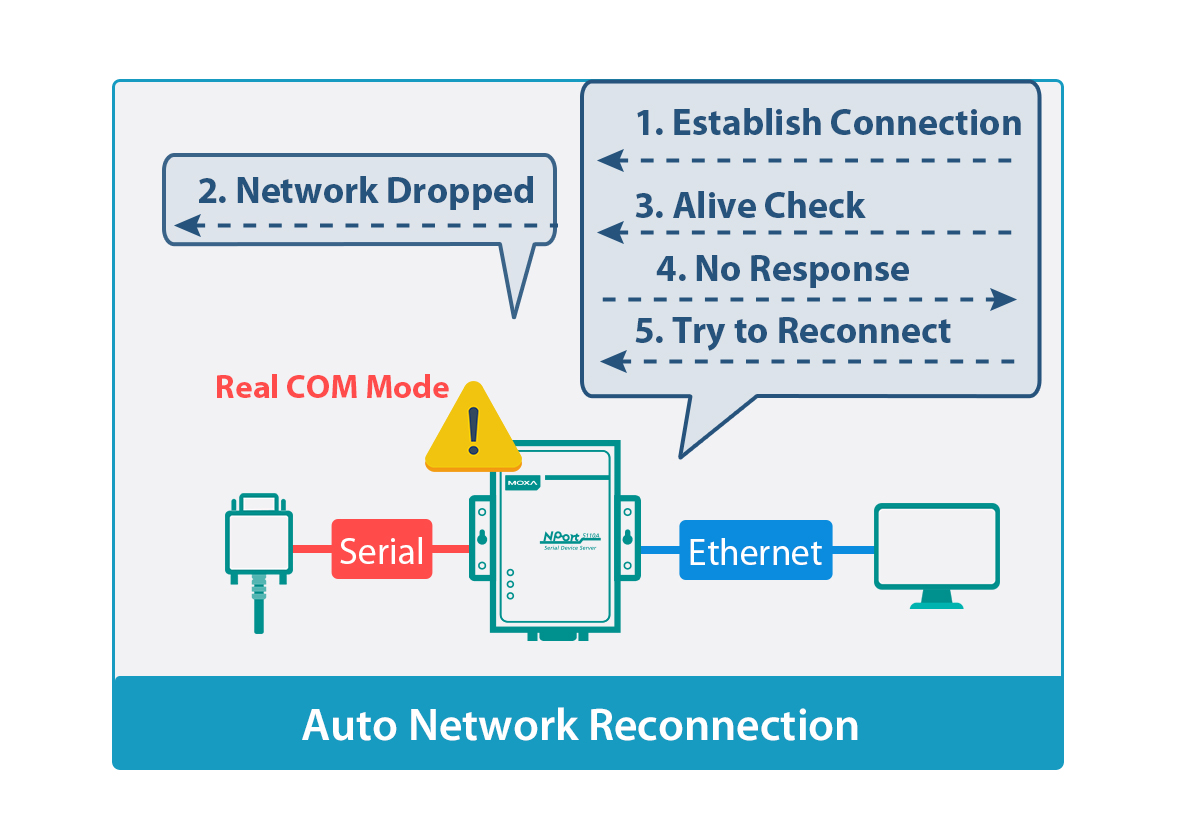

Seamless Connectivity Through Auto Network Reconnection

The advanced auto network reconnection feature integrated into the Real COM driver assures continuous connectivity between CNC machines and Ethernet-based systems. In the event of a TCP connection drop and lack of response from our NPort serial device servers to the Alive Check packets, the Real COM driver will make repeated attempts to re-establish the TCP connection, eliminating the need to close ports and reopen software for reconnection.

Benefits of NPort Implementation

Enhanced Transmission Efficiency Using Tx Mode and Fast Flush

To attain operational performance close to that of a native COM port, the Real COM driver offers functionalities that boost transmission efficiency in CNC machine monitoring applications. The Tx Mode function includes a Hi-performance mode, enabling the NPort driver to notify the application program once data transmission is completed. This enhances transmission efficiency and provides improved throughput compared to the standard mode, where notification from the NPort driver only occurs after receiving confirmation from the NPort.

Fast Flush is a feature specifically designed for Windows operating systems. In certain scenarios, user programs use the Win32 PurgeComm() function before reading or writing data. If the program employs this PurgeComm() function, the NPort driver continually queries the NPort’s firmware to ensure no data is pending in the NPort firmware buffer before flushing the local buffer, causing delays in response times. To cater to applications requiring swift responses, the Fast Flush function promptly flushes the local buffer without firmware queries, enhancing transmission efficiency.

Case Study 2: AGV Monitoring

Automated Guided Vehicles (AGVs) streamline lifting and transporting operations in manufacturing facilities or warehouses, driving efficiency gains and labor cost reductions. Typically guided by magnetic tape, AGVs traverse predefined paths using built-in guide sensors (e.g., RFID). Application software consistently sends location requests to AGVs to validate their current positions every 50 ms until a response is received. Following location confirmation, task commands are issued. Many applications impose specific timeout limits for data transmission. If the AGV controller fails to respond to location requests promptly, the application will continuously resend the request, thereby impeding overall communication efficiency.

Benefits of NPort Implementation

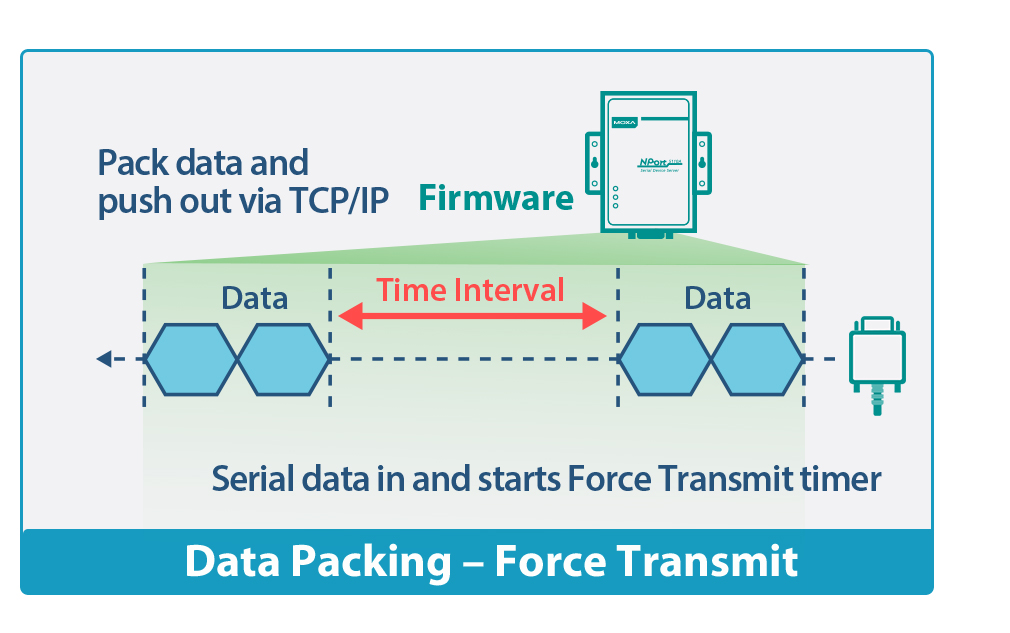

Regulate Transmission Time With Data Packing and Force Transmit

The NPort Real COM driver supports the Data Packing function, determining the optimal method for packing serial data for transmission to ensure seamless communication in AGV operations. Serial data can be packed based on specified packet lengths or upon detecting special characters. In cases where there are no defined rules for data packet creation or incomplete data packets need to be sent, the Force Transmit function allows setting a maximum time interval to await a complete serial data stream. The inter-character timeout interval defines this function, compelling the firmware to pack serial data in the same data frame within the specified timeframe. By activating this function, the NPort serial device server transmits buffered data via TCP/IP only when the internal buffer reaches capacity or the inter-character timeout is exceeded.

Our NPort serial device servers offer a diverse range of functions for various operation modes to meet industrial application requirements. You can access our comprehensive guide to explore additional features. Additionally, our NPort serial device servers incorporate security measures and provide extensive OS driver support to ensure convenient and secure connections of your serial devices to modern systems. For more information, visit our website.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024