The realm of the Industrial Internet of Things (IIoT) produces an immense volume of data that must also be preserved. Accordingly, there is a rising necessity for additional data centers to cater to the escalating demand for data storage management, leading to an increase in energy consumption. Concurrently, entities such as factories, supermarkets, and other high-power-consuming applications confront the challenge of ameliorating energy efficiency for their power-intensive equipment and devices. To navigate this landscape, operators of data centers and owners of applications need to devise strategies to manage numerous servers and power-dependent equipment while optimizing energy consumption. Power distribution units (PDUs) are instrumental in handling and dispensing power to assorted equipment. Presently, intelligent PDUs with metering and switching capabilities that can be controlled remotely have experienced noteworthy market expansion due to the surging demands for remote monitoring. Indeed, a recent industry report1 has pinpointed the escalating requirement for data center monitoring solutions as the primary driver of PDU market growth. Monitoring PDUs within your application empowers you not only to optimize energy consumption—by capturing daily power usage for billing calculations and energy regulation—but also to gather insights on the condition of your PDUs for maintenance purposes.

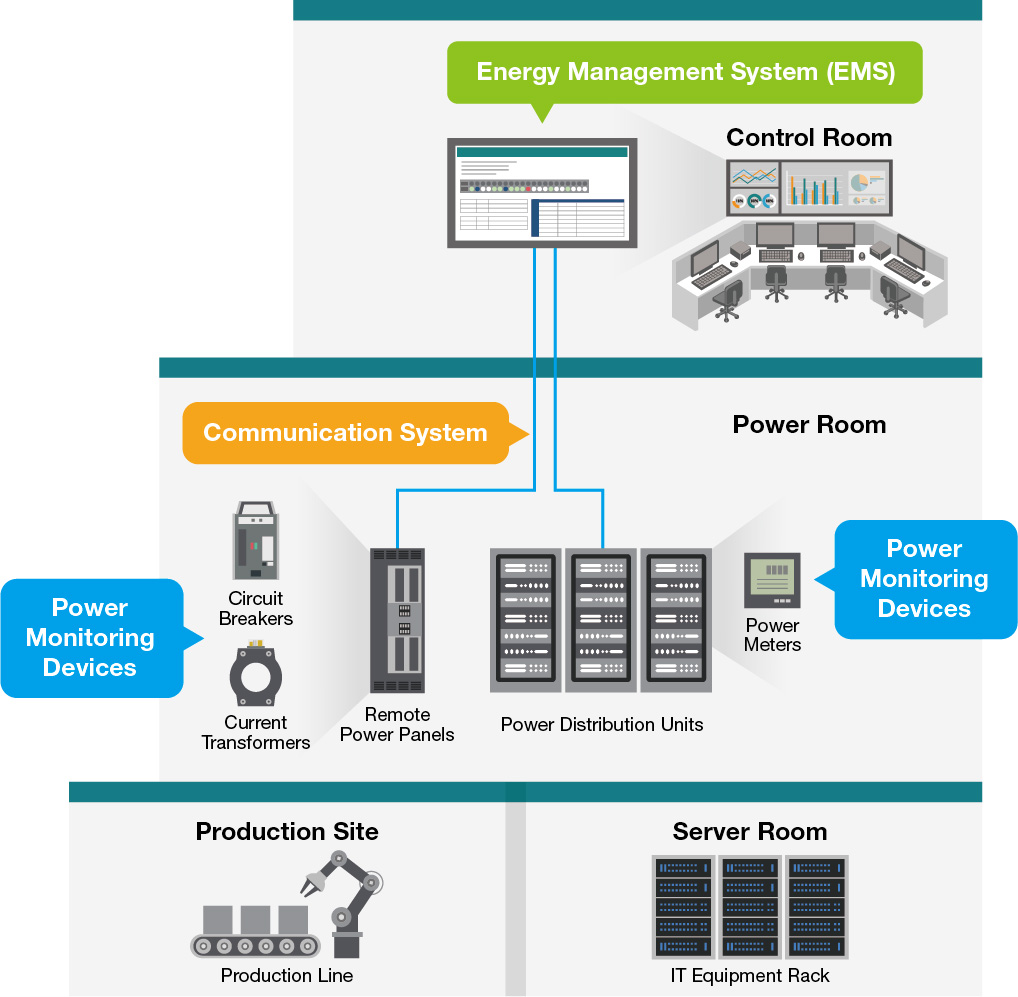

To harness the advantages of monitoring PDUs, an energy management system (EMS) must collect meter data from PDUs, enabling operators to manage, monitor, and refine PDU performance. Furthermore, remote power panels (RPPs) can serve as an extension of PDUs to bolster power distribution capacity by supplying additional circuits. Hence, it is imperative to monitor circuit breakers and current transformers to ensure that power distribution through diverse circuits remains under management.

Establishing dependable connectivity between the EMS and power equipment, such as PDUs and RPPs, is crucial to ensure seamless and optimized power distribution. Here are some recommendations to fortify connectivity:

Assess Your Project Stage to Optimize Connectivity

Upon making the choice to monitor PDUs and RPPs in your application environment, the approach for enabling connectivity hinges on your implementation blueprint. Besides linking power meters, circuit breakers, and current transformers that may adopt varying protocols and interfaces from your EMS, contemplate the following queries to select the appropriate solution:

- Are you retrofitting existing PDUs or introducing new ones?

- Does your wiring design accommodate the task?

- How many PDUs do you intend to network?

Your answers to the preceding inquiries will inform whether you require a single-port or high port-density connectivity solution. For instance, if retrofitting existing PDUs in a relatively small-scale setup within confined space, a compact single-port connectivity solution could be ideal. Conversely, in scenarios with ample space for deploying multiple new PDUs, high port-density connectivity solutions could facilitate cost savings.

Simplify Installation and Maintenance Efforts

Selecting a user-friendly connectivity solution can minimize time and effort. During installation, wiring can be cumbersome when connecting multiple PDUs to the same network. Verify if your connectivity solution offers features like Ethernet cascading, which streamlines wiring across several PDUs and RPPs to the EMS situated in the control hub. Once your PDUs and RPPs are operational, the networking components will necessitate backups and periodic updates. User-friendly software tools provided by your connectivity solutions can streamline device configuration and maintenance tasks.

Augment Operational Reliability

In the event of unforeseen network disruptions, data loss from meters could result in misestimations of power consumption, culminating in erroneous billing and incomplete power data for analysis. To bolster your power monitoring system’s reliability, contemplate backup mechanisms from diverse angles. Commence with the networking components. Features like dual-power inputs and high EMI immunity can shield networking devices from electrical interference. Subsequently, devise a redundancy strategy for your network transmissions. An array of network redundancy functionalities are available in the market. When appraising these options, evaluate whether their recovery times are suitable for your power monitoring objectives.

As a prominent authority in industrial connectivity, Moxa has aided clients worldwide in creating seamless and dependable communication for their power consumption monitoring schemes. Browse through our case studies to observe how other businesses have established communication systems for their PDUs and RPPs with Moxa’s solutions.

Require guidance in selecting networking or connectivity products for your project? Download our E-book and acquaint yourself with the essential criteria for selecting suitable products tailored to your requirements.

1Source: https://www.fortunebusinessinsights.com/industry-reports/power-distribution-unit-market-100424

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024