With the rise of Industrial IoT applications, an astonishing number of industrial devices are connected to the Internet, and this figure continues to increase annually. According to a report by the International Data Corporation in 2019, the estimate is that it will reach 41.6 billion endpoints by 2025. It’s even more astonishing the amount of data each device generates. An investigation by the Harvard Business Review has shown that “less than half of a company’s structured data is actively utilized in decision-making and less than 1% of its unstructured data is analyzed or utilized at all”. As a result, businesses and industry professionals are resorting to AI (Artificial Intelligence) and ML (Machine Learning) solutions for their IIoT applications to obtain a comprehensive perspective and make quicker intelligent decisions.

AIoT (Artificial Intelligence of Things) pertains to the integration of AI technologies into IoT applications to boost operational efficiency, human-machine interactions, and data analytics and management. For instance, an increasing number of businesses are adopting computer vision or AI-driven video analytics for categorization and identification functionalities in their applications. From data interpretation in remote monitoring and preventive maintenance, to recognizing vehicles for traffic light control in smart transportation systems, to indoor/outdoor surveillance robots and agricultural drones, to automatic optical inspection (AOI) of minute defects in various products, computer vision and video analytics are amplifying productivity and efficiency for industrial uses.

In several real-world scenarios, especially in broadly distributed systems situated in remote regions, transmitting large quantities of raw data continuously to a central server may not be feasible. To minimize latency, data transmission and storage expenses, and enhance network availability, solution providers and application architects are shifting AI and ML capabilities to the network edge to enable more potent preprocessing capabilities directly in the field. Indeed, by linking your field devices to edge computers equipped with robust local processors and AI, it’s no longer necessary to transfer all data to the cloud for evaluation.

Selecting the Appropriate Edge Computer Yields Significant Benefits

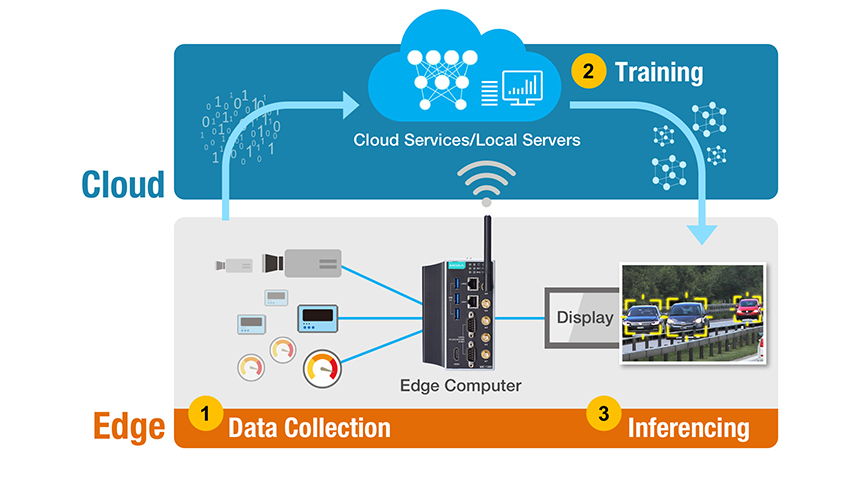

The crux of AIoT edge computing lies in allowing AI inferencing in the field instead of relaying raw data to the cloud for processing and analysis. To successfully execute AI models and algorithms, industrial AIoT applications necessitate a dependable hardware platform at the edge. When picking your edge computing solution for AIoT, you may need to contemplate the processing prerequisites for various stages of the AI implementation and the settings in which the computers are implemented.

Processing Requirements

Given that the three stages in constructing an AI edge computing application—Data Collection, AI Model Training, and AI Inferencing—employ distinct algorithms to conduct diverse tasks, each phase presents its own set of processing demands. Depending on the intricacy of the data collected, the computing platforms utilized in data collection normally rely on Arm® Cortex® or Intel® Atom®/Core™ processors. AI model training necessitates advanced neural networks and resource-intensive machine learning or deep learning algorithms and thus are generally performed utilizing cloud-based services and tools. However, it’s essential to deploy them on edge computers that feature a conversion tool for adapting the trained model to operate on specialized edge processors/accelerators, like Intel® OpenVINO™ or NVIDIA® CUDA®. AI inferencing encompasses numerous edge computing levels, each with its unique set of requirements.

Environmental Considerations

You also need to factor in the physical location where your application will be deployed. Industrial applications set up outdoors or in harsh environments—such as smart city, oil and gas, mining, power, or outdoor patrol robot applications—should encompass a wide operating temperature range and suitable heat dissipation mechanisms to ensure reliability in sweltering hot or icy cold conditions. Specific applications demand industry-specific certifications or approvals, such as fanless design, explosion-proof construction, and vibration resistance. Given that many real-world applications are installed in confined cabinets and are subject to size constraints, compact edge computers are preferred. Also, profoundly distributed industrial applications in remote areas may necessitate communication over a dependable cellular or Wi-Fi connection. Another consideration is that redundant wireless connectivity with dual SIM support may also be required to guarantee data transfer in instances where one cellular network signal is weak or disrupted.

To delve deeper into deploying edge-computing platforms for AIoT in concrete industrial applications and examples, download our AIoT white paper.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024