The continual decline in global oil prices is negatively impacting the cost-intensive upstream oil activities and economies reliant on oil production. Oil corporations are now under pressure to deploy modern cost-efficient networking solutions across their operations, all while maintaining stringent safety and security standards.

When developing an intelligent oil field, three key factors must be taken into account:

- Safeguarding

- Upgrading Legacy Systems

- Real-Time Data Management

Safeguarding

Attaining comprehensive cybersecurity and network protection necessitates finding the right balance between hardware robustness and firmware capabilities.

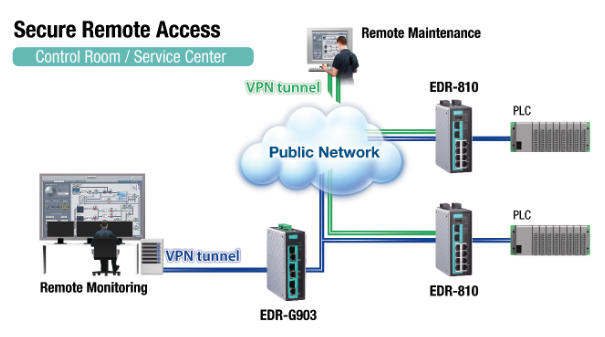

To establish a scalable intelligent oil field network with plug-and-play functionality, it is crucial to have straightforward network setup features that reduce human errors and facilitate integration with existing SCADA systems. Utilizing industrial routers with a throughput of up to 500 Mbps enables the network to accommodate future expansions and data-heavy operations like remote wellhead surveillance. By combining user-friendliness with VPN/Firewall/NAT support, your intelligent oil field network will be both efficient and secure.

The diagram above demonstrates how Moxa’s array of all-in-one industrial secure routers can secure connections for remote monitoring and maintenance via VPN tunnels over public networks.

Upgrading Legacy Systems

The adaptability of industrial networking technology can greatly simplify the transition to fully leveraging advanced IP SCADA solutions.

Industrial wireless and Ethernet technologies enable wellhead operations to monitor and control field assets with minimal deployment costs and manpower. Furthermore, the adoption of Ethernet and wireless devices supports interoperability and backward compatibility with fieldbus protocols, facilitating the parallel advancement of sensor technology and IP SCADA systems. Legacy devices in today’s oil fields utilize a range of data interfaces such as DI/DO, RS-232/422/485, Ethernet, and USB. A reputable networking provider that offers connectivity across these interfaces makes it easier to extend the use of existing legacy DCS infrastructures.

Moxa’s protocol gateway enhances the visibility of protocols at field sites.

Real-Time Data Management

Efficient real-time data processing requires a robust industrial network.

The barriers preventing oil companies from adopting Ethernet and wireless gateway technologies are diminishing in the face of potential operational savings. To effectively manage the growing data volumes from smart meters in oil fields, data needs to be utilized for instant responses. This poses a challenge for outdated serial networks and fieldbus applications. Moxa is aiding companies in the smart oil field transition by linking the application layer with the multitude of sensors dispersed across these intelligent oil fields.

For further insights into the networking challenges of smart oil fields, download our whitepaper.

Moxa’s Innovations for Oil & Gas Environments

Access the brochure to discover how Moxa’s integrated networking, computing, and automation solutions are employed in hazardous oil and gas production settings.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024