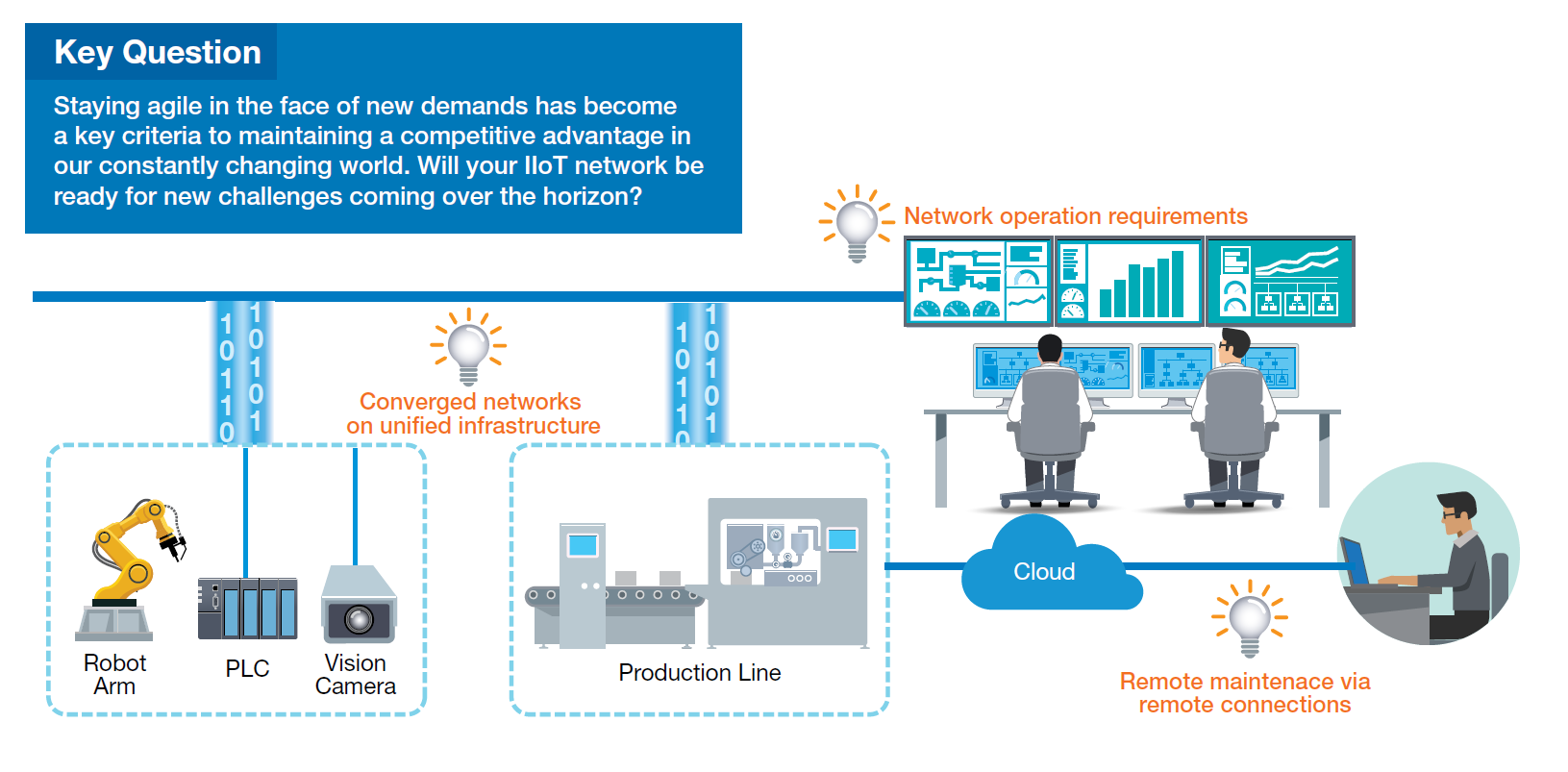

It might be alluring to relax on your accomplishments once your IIoT networks are operational. Nevertheless, change is an enduring element of life, and the industrial networking sphere is no different. While your current IIoT network may suffice for present requirements, it must also be ready for upcoming needs over the next years. What about the following decade or beyond? Change is on the horizon, and readiness is crucial.

From the inception of industrial automation, manufacturers have favored specialized protocols and systems over standard Ethernet technologies for specific industrial applications. However, with the IIoT sector projected to grow at a CAGR of 24% by 2023, the future industrial networks will likely need to handle significant data transmission between interconnected devices or gather data from remote devices. In light of these escalating demands, your level of preparation for the future of industrial networking can significantly impact your ability to tackle new challenges. This section outlines three factors to assist in getting your IIoT-compatible industrial networks ready for the future.

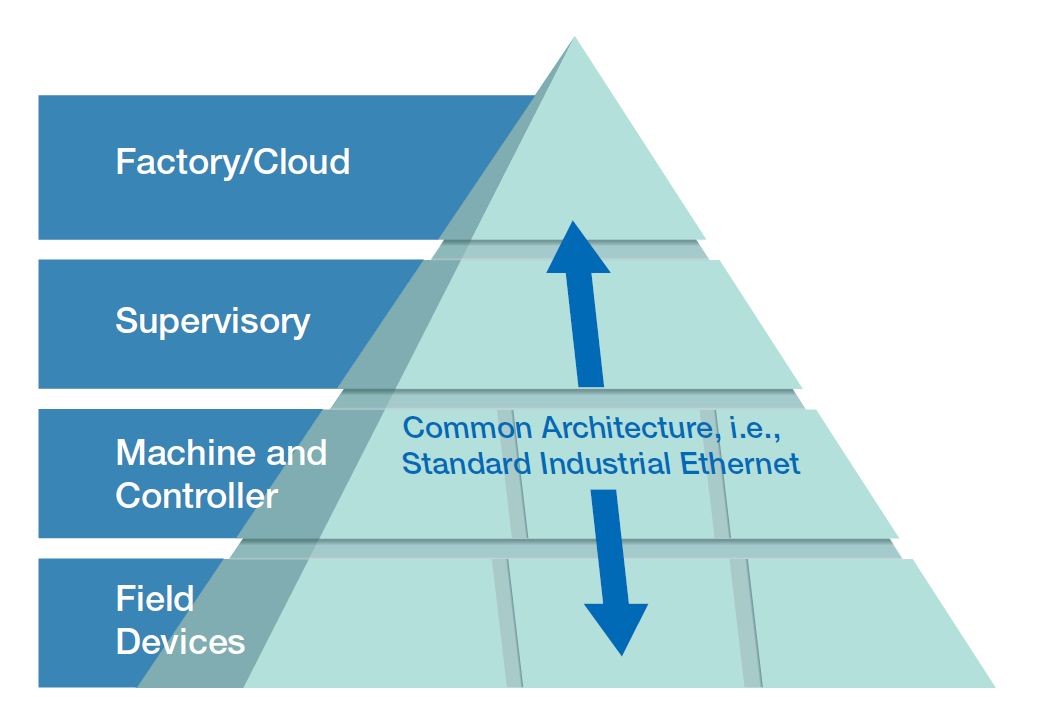

Enhance Integration Through Unified Infrastructure

Over time, various devices utilizing diverse industrial protocols have been integrated into industrial networks to offer a range of services. In such scenarios, achieving network integration often incurs higher costs than anticipated or becomes increasingly challenging. Manufacturers can either maintain their existing isolated automation networks with numerous legacy protocols, or opt for solutions that offer deterministic services and merge these “automation islands”.

To be well-prepared for the increasing demands on your IIoT network in the future, choosing the latter option is evidently the wiser path. It is essential to anticipate potential industrial protocols and ensure your networks can be restructured when new demands arise. Time-sensitive networking (TSN) represents a suite of new standards presented by the IEEE 802.1 TSN Task Group as a sophisticated toolbox. By leveraging TSN, you can establish open, unified networks using standard Ethernet technologies that allow for future adaptability. Additionally, consider solutions promoted by leading proponents of this technology as they actively engage in TSN events to foster ecosystem completion and ensure interoperability across various vendors.

Reach Your Remote Machines Anywhere With Effortless Cloud Services

Cloud-based remote access presents numerous advantages for IIoT users, such as reducing travel time and costs for sending maintenance personnel to multiple remote locations. Moreover, secure cloud-based remote access can provide adaptable and scalable connections to meet the evolving requirements of the future. Nonetheless, operational technology (OT) engineers in industries like water treatment plants, machine manufacturing, and other IIoT sectors may find it challenging to set up and sustain their cloud servers for new services and applications. Setting up new infrastructure, even in the cloud, requires considerable effort. Fortunately, OEMs and machine manufacturers can now offer secure cloud-based services and remote access to customers without the need to manage their cloud servers themselves.

One critical aspect to scrutinize is the cloud server licensing model. Initial costs for limited server hosts may seem low, but these apparent savings might render your project economically impractical due to restricted connection scalability. Additionally, consider the availability of central management features to expand remote connections effectively in the future. Consequently, carefully evaluate the costs and benefits of integrating secure remote access into your industrial networks. Opt for solutions that can eliminate the mentioned challenges and enable you to focus on delivering greater value and advantages to your clients.

Visualize Your Network Status for OT and IT Professionals Alike

You may have come across depictions in movies or news photos showing a metro system control room with monitors displaying the statuses of each station, train locations, and more. Managers must swiftly assess the situation and take appropriate actions based on the aggregated information on the screens before them. This visibility ensures effective control. As industrial networks grow in complexity with greater connectivity, pinpointing the root cause of issues and maintaining adequate network visibility can become challenging. Control engineers often resort to trial and error to rectify the system, a tedious and time-consuming process.

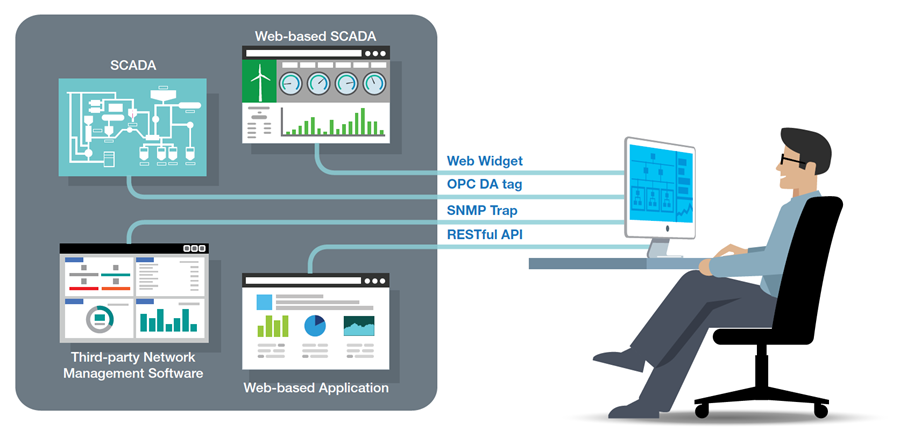

Therefore, to simplify and manage expanding industrial networks, network operators require integrated network management software to make informed decisions across network deployment, upkeep, and troubleshooting. As your systems expand, you must address several network integration aspects. Solely managing industrial networks at local control centers may become untenable in the coming years, particularly when melding existing systems with new ones. Hence, utilizing network management software with integration interfaces, like OPC DA tags for SCADA integration or RESTful APIs for external web services, is critical. Additionally, an interface for seamless third-party software integration is imperative to ensure future adaptability.

As a pioneer in industrial networking expertise, Moxa offers various revolutionary technologies and solutions, including secure cloud-based remote access and network management utilities, that already fulfill the aforementioned three factors to expedite your network readiness for future IIoT applications. For further insights into industrial networking, download our E-book.

1. The Industrial Internet of Things Market Forecast, MarketWatch, March 2019

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024