Remote support and problem-solving facilities are empowering original equipment manufacturers (OEMs) and machine developers to assist their clients with improved efficiency, while also aiding them in boosting productivity. These distant services not only enable quicker and more intelligent decisions but also decrease the duration and expenses of post-sales support and maintenance for machinery and devices.

Despite the fact that utilizing a virtual private network (VPN) to remotely connect to off-site industrial machinery and equipment is not a novel technology, OEMs and machine developers frequently encounter supplementary obstacles like assorted customer privacy apprehensions, intricate VPN configurations, IP address management, and conformity with IT security standards.

To tackle these obstacles, cloud-based distant connections can offer effortless, safeguarded, and adaptable remote access to clients’ machinery and equipment. We will now explore two typical scenarios and observe how they can derive advantages from protected cloud-based remote connections.

Scenario 1: Distant Data Retrieval

Within a water treatment facility, untreated water must undergo a procedure of treatment and refinement to generate potable water that is safe for human consumption. To accomplish this, numerous sensors are employed to gauge the water quality. These sensors are spread out across hundreds of installations and require constant monitoring. Alongside water treatment and purification, the handling and distribution of water post-treatment is equally crucial to guarantee the continuous safety of water for human consumption.

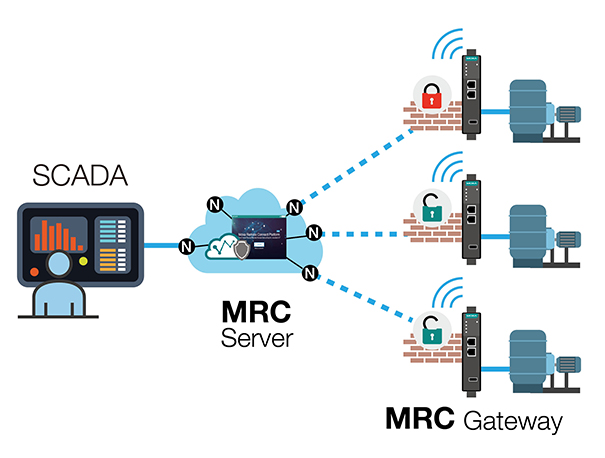

A preventive measure to avoid water recontamination in the distribution network is retaining residual disinfectants in the treated water. To guarantee that disinfectant levels do not reach hazardous thresholds, the water is continuously monitored by sensors positioned in the pipes. These sensors transmit data through SCADA systems to devices installed in roadside cabinets along the distribution lines. Another advantage of these systems is that they enable the tracking of water consumption by each household or facility to ensure accurate billing. Traditional VPNs are often employed at these locations, but expanding and managing them becomes a challenge as more residences or facilities are constructed and require monitoring of their water supply.

Benefits of Cloud-based Distant Connections

Due to the extensively decentralized structure, cloud-based remote communications can offer a simpler and more economical means for water and wastewater treatment centers to extract data. Cloud-based remote communications mitigate the necessity for setting up and acquiring additional VPN servers and clients when a new field location requires monitoring, as well as avoid the expenses of acquiring public IP addresses needed for each VPN server and client. Moreover, managing certificates for each connection is simplified when utilizing cloud-based remote communications.

Scenario 2: Distant Maintenance

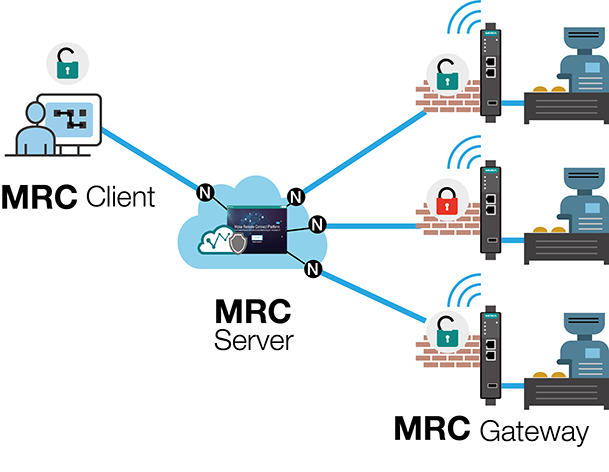

Food processing machines are used to automate the large-scale production and processing of food. For food manufacturers to expand their operations, it is imperative that their machines do not suffer from network outages. Companies engaged in food production anticipate rapid response times from the OEM when machine maintenance is needed to safeguard operations from disruptions. To ensure timely responses that prevent interference with normal manufacturing activities, machine developers require a secure and more effective approach to troubleshoot and perform maintenance duties without dispatching personnel to every site.

Advantages of Cloud-based Distant Connections

Offering unrestricted remote access to machines on the production floor would expose business proprietors to unacceptable security vulnerabilities and open avenues for cyberattacks. Thankfully, cloud-based remote access not only empowers engineers to handle various maintenance tasks without visiting each customer’s factory in person but also allows customers to manage network access. One option available to machine developers is providing customers with a physical key that must be activated to enable remote machine access. Customers can also restrict the usage of specific programs on a machine by remote service engineers. Additionally, customers can confine remote connections to particular network segments, preventing off-site support engineers from accessing the entire network.

The Present Challenge

While cloud-based remote access presents evident perks to IIoT customers, operational technology (OT) engineers, water and wastewater treatment managers, and machine developers may perceive establishing and maintaining their own cloud servers for delivering new services and applications as tedious. Indeed, setting up new infrastructure, even if it resides in the cloud, demands a substantial effort.

Convenient Protected Cloud Solutions

Fortunately, OEMs and machine developers can now deliver protected cloud-based services and remote access to customers without the obligation of managing their personal cloud servers. Particularly, Moxa Remote Connect (MRC) gateways offer the MRC Quick Link alternative to provide straightforward, secure, and flexible remote access to machines and equipment via the cloud. Simply enable MRC Quick Link by registering your MRC gateway on the Moxa Software License Portal, and each activated MRC Quick Link grants five concurrent online nodes and 5 GB of monthly data.

To discover more about how MRC Quick Link caters to diverse communication necessities and enables scalable remote access flexibility, kindly visit the Moxa Remote Connect microsite.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024