Engineers are acutely mindful of the significant risks involved in strategizing the structure of a Modbus-RTU-to-Modbus-TCP network. The complexity is magnified in networks with a substantial number of Modbus serial devices, leading to potential connectivity issues at field locations. It can be disheartening when meticulous planning is disrupted in real-world scenarios.

For engineers, dedicating excessive time and resources to planning a Modbus network’s configuration and dividing devices into subcategories is counterproductive. The most arduous task lies in inputting myriad Modbus slave IDs to configure each gateway’s Modbus slave ID routing table, detailing the connections of Modbus devices to specific serial ports. Hence, it’s unsurprising that engineers seek solutions that streamline the setup process of multiple Modbus gateways.

Engineers aspire to simply dispatch Modbus requests to a Modbus gateway, which can autonomously locate the appropriate serial port connecting with the targeted Modbus device. Such advancements are especially pertinent in the age of the Industrial Internet of Things (IIoT) where numerous serial devices are transitioning to Ethernet-based networks.

Streamlining Management of Numerous Modbus Devices

An essential challenge in implementing Modbus technology is determining the requisite number of gateways for transmitting data between an extensive array of Modbus devices and supervisory control and data acquisition (SCADA) systems. Multiport Modbus gateways excel in managing a large quantity of Modbus devices compared to single-port gateways. As an instance, a 16-port Modbus gateway can substitute 16 one-port Modbus gateways. Using a multiport Modbus gateway is advantageous in scenarios where space and budget constraints exist, leading to more available physical space, reduced expenses, and simplified setup and management due to the requirement of fewer cables and devices. Furthermore, consolidating the numerous IP addresses needed for 16 individual gateways into a single IP address presents additional benefits for SCADA systems, such as decreased connection fees based on the number of connections.

Nevertheless, engineers must initially group these devices and connect them to specific ports on the gateway. Crafting a comprehensive Modbus slave ID routing table is vital, yet time-consuming. Two intricate routing mechanisms cater to varying needs in Modbus-based networks.

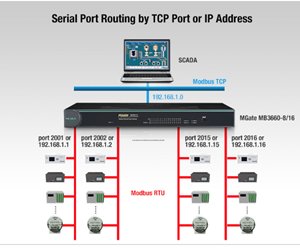

Routing via IP Address or TCP Port

Certain Modbus gateways facilitate serial port mapping via an IP address or TCP port, suitable for monitoring field devices in segments. Each Modbus slave device connected to the same serial port through daisy-chain wiring corresponds to a distinct IP address or TCP port, streamlining the grouping process. However, configuring numerous IP or TCP connections corresponding to the number of serial ports in use can be a time-intensive task in extensive Modbus environments with a high number of multiport gateways, accompanied by substantial connection fees and manual maintenance of serial-port mapping.

Routing by Leveraging a Gateway’s Modbus-ID Routing Table

Engineers prioritizing reduced connection fees and unified device monitoring often opt for a Modbus slave routing table. This table serves to link Modbus devices to specific serial ports on a gateway. Once the gateway receives a Modbus request for a particular device, it utilizes the Modbus slave ID routing table to direct the request to the corresponding serial port linked to the target device.

However, managing a Modbus slave ID is labor-intensive. Engineers must group slave IDs and connect each group to distinct serial ports. Routing rules must be set repeatedly for each port on a gateway. The complexity escalates if multiple Modbus slave IDs are connected to individual ports, necessitating meticulous tracking and rule setting, amplifying the effort required.

Single-Click Operation

A novel technology promises to simplify engineers’ tasks significantly. This technology enables the gateway to automatically detect the connected port of the targeted Modbus device with a single click, ensuring precise dispatch of Modbus requests without manual creation of Modbus slave ID routing tables, reducing time and costs while eliminating potential errors and the need for physical verification at field sites.

Moxa’s Comprehensive Solutions

Moxa’s MGate MB3000 Series features the Auto-Device-Routing function, integrated into high-performance Modbus gateways with 2, 4, 8, or 16 serial ports. The series also supports routing via IP address or TCP port. For further details, refer to our white paper on automating Modbus gateway routing setup.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024