The market for automated material handling equipment is poised for significant expansion in the coming years*. This growth trend, which has been anticipated, was recently accelerated in the spring of 2020 due to two major catalysts. Specifically, the surge in e-commerce businesses and the implementation of social distancing protocols on factory floors. In recent times, e-commerce warehouses have become highly sought after due to the escalating demand from online shopping. In light of this increased demand, efficient and reliable AS/RS systems play a critical role in maintaining the seamless functioning of warehouse logistics systems.

Alongside the growth in e-commerce ventures, factory owners are also revamping their factory layouts to comply with social distancing directives. The widespread adoption of automated guided vehicles (AGVs) is aimed at reducing human contact and boosting operational efficiency. As AGVs and AS/RS systems gain popularity, machinery OEMs and system integrators are looking to establish robust connectivity frameworks to ensure smooth operations in warehouses and factories. Since AGVs and AS/RS are consistently in motion, rapid and stable wireless connectivity emerges as an essential prerequisite. The primary challenge lies in constructing a dependable wireless communications network for these systems.

This article will shed light on some critical factors that machinery OEMs and system integrators must consider when erecting robust AGVs and AS/RS systems.

Essential Points to Bear in Mind

1. Optimal Reliability Through Industrial-grade Designs

On factory floors, there exists a myriad of unforeseen and often inevitable electrical interferences that can disrupt wireless transmissions or potentially damage wireless communication tools. Let’s consider a scenario in a motorcycle assembly plant. Several pieces of production machinery can generate unintended electrical potentials across the workshop. Furthermore, actual environments may contain ground loops that could negatively impact wireless devices. Similarly, the conveyor belts used for product movement in the assembly line rely on motor-driven equipment to operate. The electromagnets and electrical currents generated by this machinery can also impede wireless communication. Lastly, the wireless devices mounted on AGVs and AS/RS hardware are subjected to constant vibrations during vehicle movement, further challenging wireless performance.

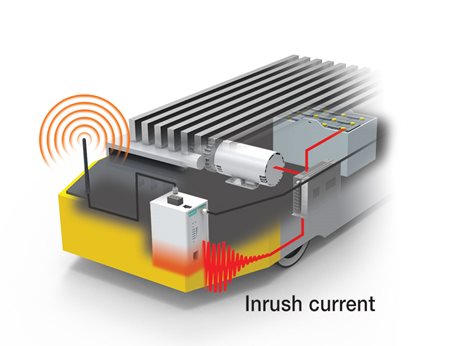

Diagram 1: Safeguarding Against EMI with RF and Power Isolation

Given these circumstances, prioritizing a robust, industrial-grade wireless solution becomes imperative. Wireless clients and access points can be fortified with RF and power isolation to shield the devices against electrostatic discharge damage and abrupt inrush currents from motors. These devices also exhibit wider operating temperature ranges and feature high ingress protection levels to ensure consistent wireless connections, even in environments with substantial ambient interference. Through these enhancements, industrial-grade devices are engineered for prolonged durability.

2. Ensuring Continuous Operations with Seamless Wireless Connectivity

In numerous warehouses, AS/RS machinery swiftly and effectively moves and retrieves goods. This is made possible through wireless roaming. Roaming technology facilitates wireless clients in continuously seeking out and switching to the nearest access point with the strongest signal prior to the wireless connection dropping. Given the mobility of these vehicles, evaluating the wireless environment is crucial to guarantee smooth roaming transitions and uninterrupted connectivity.

Additionally, the extent of Wi-Fi coverage directly impacts the quality of wireless connections. Wi-Fi coverage dictates how rapidly a wireless device can detect nearby access points, thus enabling more reliable roaming. Opting for wireless devices equipped with MIMO (multiple-input and multiple-output) functionality can further enhance the capacity of a radio link to expand Wi-Fi coverage. This, in turn, enhances wireless performance and obviates the necessity of additional access point installations.

Subsequently, system integrators should ascertain if the chosen wireless solution supports communication between PLCs and wireless access points/clients. Determining network communication requisites can aid in identifying the suitable WLAN settings for the intended deployment settings. For guidance and industry best practices, refer to our white paper on PROFINET Over Industrial WLAN Infrastructure.

While selecting wireless communication tools, verify if the device supports millisecond-level roaming technology, consider utilizing external antennas for enhanced deployment flexibility and broader Wi-Fi coverage, and adhere to configuration directives from the device provider.

Diagram 2: Ensuring Seamless Wireless Connections with Sufficient Wi-Fi Coverage and Roaming Technology

3. Strengthened Network Security through Built-in Features and Management Software

Contemporary discussions frequently spotlight network security as a paramount concern. Basic network management oversights can inadvertently introduce cybersecurity vulnerabilities to the entire network. For example, if wireless clients can connect to access points without any form of authorization or authentication mechanism, this unrestricted access could lead to network breaches and potential shutdowns of AGV and AS/RS systems. It is strongly advised to secure all wireless communication devices post-configuration and prevent unauthorized devices from accessing the wireless network, thereby enhancing network security.

To enhance management of wireless network security, contemplating the use of management software to visualize the network environment and regulate node connections can be beneficial.

Diagram 3: Implementing Management Software to Deter Unauthorized Networking Node Connections

Moxa’s Comprehensive Solution

Moxa has played a pivotal role in assisting machinery OEMs and system integrators globally in enhancing their AGVs and AS/RS systems to ensure optimal dependability and efficiency. Moxa’s AWK Series AP/bridge/client solutions unite a sturdy design with high-performance Wi-Fi connectivity to deliver secure and trustworthy wireless connections. With the MXview network management software and AeroMag technology, clients can seamlessly set up, manage, maintain, and troubleshoot their network. Explore our microsite, The Missing Piece for Your AGVs and AS/RS Systems, to delve deeper into these solutions.

* Source: Report Hive

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024