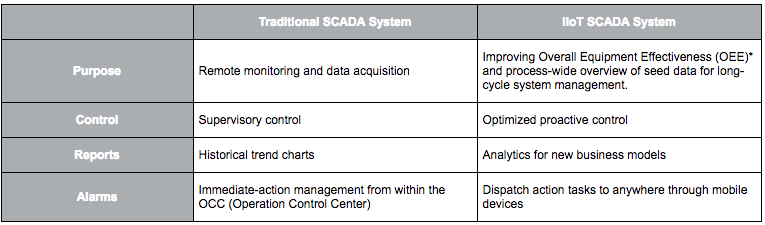

Contemporary SCADA systems are rapidly integrating Industrial Internet of Things (IIoT) technologies, such as cloud services or publish/subscribe protocols, to gather additional information from monitored systems. The expansion in the volume of data being handled is continuously increasing, indicating that current SCADA systems need to handle significantly more data compared to traditional SCADA systems from a decade or two ago.

*OEE reveals the proportion of resource utilization time that is truly productive.

Intelligent Data Acquisition Enhances Large Data Validity

For numerous years, the industry norm for SCADA communication between the server and clients has been “updating data by polling.” However, polling IIoT devices can lead to the accumulation of a huge amount of unnecessary data from numerous sensors, resulting in high data storage expenses and time-consuming data analyses. Utilizing the “updating by exception” approach when sensors provide data at a frequency much lower than the polling interval, such as when monitoring a machine’s ON/OFF status, can decrease the required data storage volume and boost the efficiency of data analysis.

When combined, the Moxa ioLogik 2500 series, MX-AOPC UA Server, and MX-AOPC UA Logger create a comprehensive solution that offers real-time data acquisition, data buffering in local storage devices, and automated data completeness after network failures. The MX-AOPC UA Logger imports data from the MX-AOPC UA Server into a database instantly. In the event of network failure and subsequent recovery, the logger retrieves data logs automatically from the data buffers of specific ioLogik 2500 devices with timestamps that match the disconnection period duration, before pushing the additional data into the database.

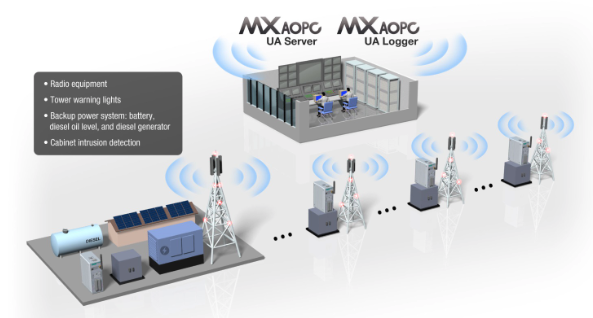

Case Study: Radio Station Equipment Monitoring

Several leading wireless service providers worldwide are searching for efficient and cost-effective methods to oversee remote and unattended sites. The conventional practice of dispatching maintenance personnel for regular onsite visits is both cumbersome and expensive. A feasible solution is enabling maintenance engineers to monitor and manage unattended sites remotely, proactively maintain and regulate their systems to avoid downtime. Furthermore, during wireless transmission disruptions, data is stored in a local RTU. Upon restoration of the wireless network connection, the data can be automatically transmitted back to the central database.

A solution provider utilizes the Moxa ioLogik 2542-HSPA-T, MX-AOPC UA Server, and MX-AOPC UA Logger in conjunction with their proprietary SCADA software on a private cloud to deliver a nationwide solution for monitoring radio station equipment. This setup allows engineers to oversee:

- radio equipment

- lighting on radio towers to ensure adherencet with flight safety regulations

- the backup power system, encompassing the battery, diesel oil level, and diesel generator

- cabinet intrusion detection indicators, equipment rooms, and restricted areas

Approximately 100 unattended sites are under observation in one application. At each site, an ioLogik 2542-HSPA-T is installed. Each ioLogik examines 12 analog inputs and transmits data to the MX-AOPC UA Server using a percentage change strategy. Additionally, the ioLogik monitors 8 digital inputs and forwards data to the server only when an exception occurs, resulting in a significant reduction in the data needing transmission. This also considerably decreases the central site’s storage requirements. If the connection between the ioLogik 2542-HSPA-T and MX-AOPC UA Server is lost, the data is stored in the local storage drive for backup. Upon reconnection, the MX-AOPC UA Logger automatically fetches the data from the local storage drive and transfers it to the central database.

The Moxa ioLogik 2542-HSPA-T, MX-AOPC UA Server, and MX-AOPC UA Logger not only simplify the real-time data transmission to the database, but they also enhance data integrity by automatically transferring supplementary data saved locally during disconnection periods to the central database. This system not only amplifies data reliability but also equips SCADA engineers with swift and precise data analysis.

For further details, download our white paper: How OPC UA Software Enhances Large Data Validity for IIoT SCADA Systems.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024