The influence the Web has had on human lifestyles has been extraordinary. It has facilitated communication and interaction in ways previously unimaginable. Recently, it has paved the way for what many predict will become more essential to daily life than the Internet itself, the Internet of Things (IoT).

One of the most promising possibilities lies in industrial applications, often referred to as the Industrial Internet of Things (IIoT), where communication and interaction capabilities can be extended to devices or entities, such as factory automation, green energy, smart grids, intelligent transportation systems, and even oil and gas applications. A report released by Strategy Analytics last year forecasted that machine-to-machine connections would increase from 368 million in 2015 to 2.1 billion by 2022. The potential of the Industrial IoT is unquestionably vast. However, before these statistics and the full potential of it become tangible in everyday life, several challenges need to be acknowledged.

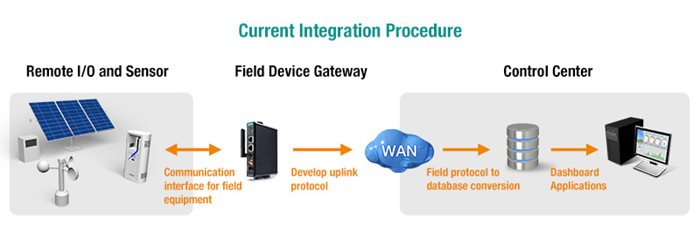

In IIoT environments, it is common for multiple devices to operate on the same network, yet often different devices support varying communication protocols. To derive true value from the Industrial IoT, the diverse devices deployed must be capable of sharing information and communicating seamlessly. Presently, data is harvested from devices and transferred to the central server. Depending on the scale of the application, numerous devices ranging from several to thousands could be involved. Subsequently, the server must process the device data for informed decision-making. The challenge of disparate devices using distinct communication protocols can be overcome by companies developing their own programs to ensure device interoperability. However, considering this is a complex and expensive integration process that could prolong installation, it is not the optimal choice for forward-thinking companies.

Given the promises of the IIoT, it is crucial not to lose sight of its fundamental purpose, which is to simplify users’ lives. As Brown University Computer Scientist Michael Littman has highlighted: If users have to learn different interfaces for their vacuum cleaners, locks, sprinklers, lights, and coffee makers, it becomes challenging to argue that their lives have been made simpler.

As an Industrial IoT environment encompasses various domains, each requiring distinct expertise, engineers from diverse backgrounds are essential for efficient project execution. For instance, many individuals in the automation sector are well-versed in industrial protocols like Modbus but lack familiarity with Information Technology and 4G LTE. Conversely, many in the IT sector are knowledgeable about communication technologies but lack expertise in industrial protocols. This scenario often leaves companies with two choices:

- Allocate a substantial budget to train current engineers on unfamiliar devices.

- Recruit new talent to fill the expertise gaps.

An increasing number of developers in Industrial IoT environments have identified the aforementioned challenges during infrastructure development. Overcoming these hurdles is crucial for successful IIoT deployments, emphasizing the importance of technologies that can reduce costs.

Firstly, to address businesses’ pain points and enable successful development and deployment of IIoT applications, information sharing and seamless interaction among diverse devices are crucial. Secondly, resolving the issue of engineers working with unfamiliar protocols or applications where they lack specialized knowledge is essential for the IIoT to realize its full potential. Ultimately, streamlining costs for businesses and accelerating product launches will be paramount for any Industrial IoT environment.

Moxa has participated in numerous Industrial IoT project implementations over the years, providing insight into long-standing business challenges. One solution developed is a software suite named ThingsPro, designed to address these issues. Installed on a field gateway, such as Moxa’s UC-8100 series, ThingsPro’s primary function is to collect data from field devices and convert it into a format conducive to communication with the central server and database.

ThingsPro currently comprises two tools, Data Logger and Wireless Manager, which mitigate compatibility issues across protocols and reduce engineers’ workload during installations. Data Logger converts information from diverse end devices for transmission to the database, generating actionable insights for businesses. Wireless Manager assists individuals familiar with automation technology in connecting their field devices to a WAN by handling the conversion process on their behalf. Consequently, engineers need not expend additional effort acquainting themselves with wireless connectivity technology, allowing them to focus on device data collection and analysis, the ultimate goal of an IIoT project. This streamlined approach enables businesses to deploy equipment more rapidly, complete projects sooner, and develop more efficient solutions.

As Industrial IoT environments expand swiftly, the demand for the ThingsPro Software Suite surges due to its ability to expedite solution launches for businesses by acting as a wireless manager for those unversed in ICT protocols and a data logger for individuals lacking automation technology expertise. Moreover, it boasts a significantly lower total cost of ownership compared to other solutions. Notably, the built-in cellular module in the Gateway, supported by ThingsPro, functions as a wireless router and performs data logging tasks that would typically require a computer. This eliminates the need for a separate computer and wireless router, significantly reducing costs.

Additionally, to accommodate various Modbus devices, the Modbus template is reusable for adding new Modbus units sans reprogramming configurations. Gateway settings and template configurations can be imported/exported for swift deployment via the GUI. Furthermore, users can troubleshoot and maintain historical log files of the system through ThingsPro. For further information on ThingsPro and Industrial IoT, please visit this site.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024