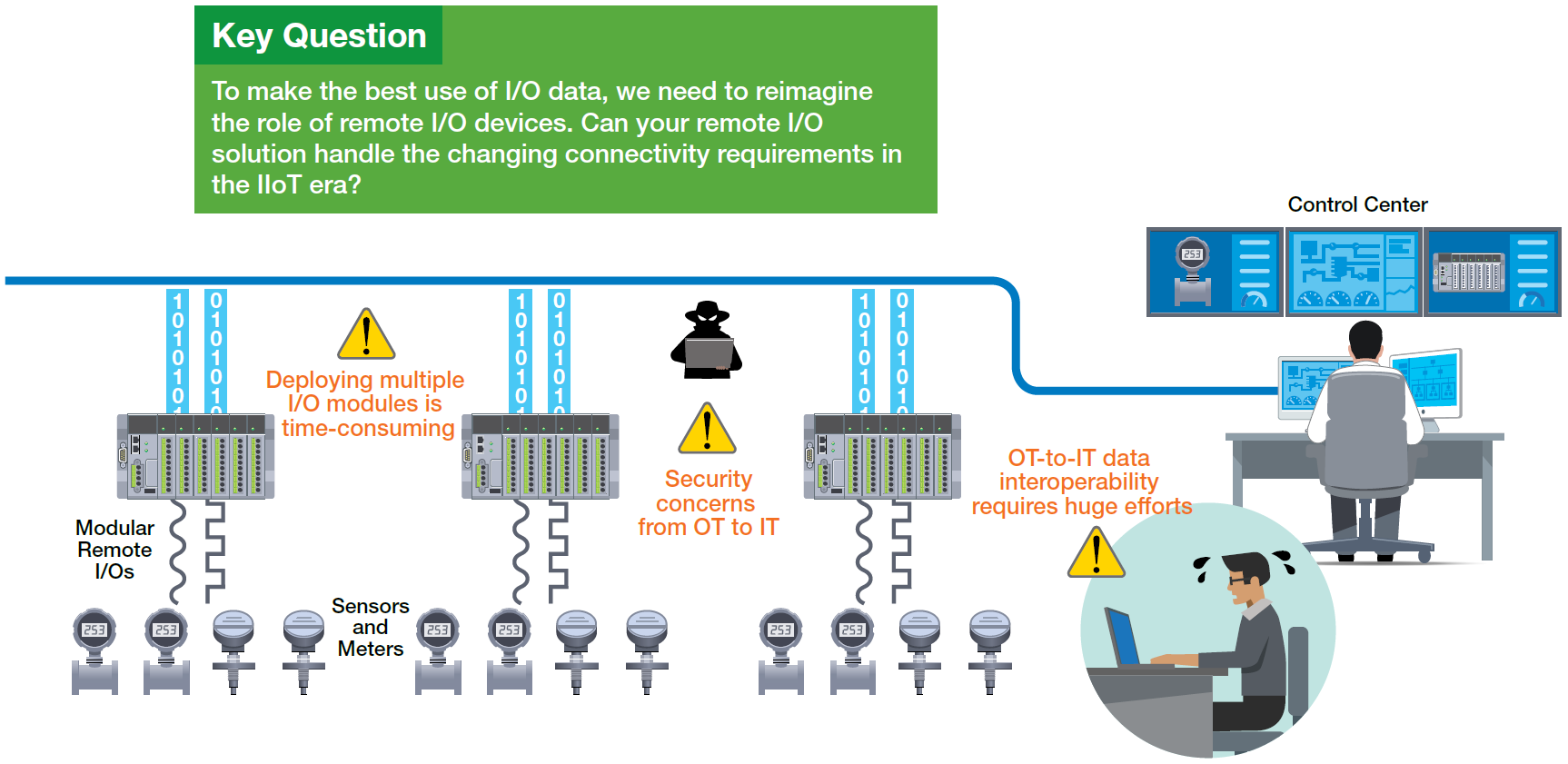

To gain meaningful insights for Industrial Internet of Things (IIoT) applications, data is an essential component. Remote I/O devices, which facilitate the transmission of input and output signals to and from sensors, controllers, and equipment in the field, may not possess the futuristic appeal of “smart” automated robots often associated with the IIoT. However, these fundamental I/O workhorses play a crucial role in providing the remote I/O data necessary for your operations.

Typically situated at field sites, remote I/O devices allow access to data and environmental monitoring from a central control center located at a distance. The acquisition of I/O data not only ensures the efficient daily functioning of your field application but also presents opportunities for insights that can enhance productivity.

Despite the growing complexity of IIoT systems and applications, traditional data acquisition methods are being tested. Modular remote I/O devices offer distinct advantages by enabling customization of I/O modules directly on the remote I/O device. This flexibility grants you the freedom to select specific types of I/O modules, decide when to deploy modules for flexible expansion, and determine the usage of modules based on your chosen communication methods. Although modular I/O devices may not be the latest innovation on the market, the flexibility they offer continues to elevate our expectations regarding remote data acquisition from each node.

Essential Factors to Consider When Selecting a Modular Remote I/O

It is imperative to opt for a modular remote I/O solution that optimizes the utilization of collected data throughout the entire process, from installation to operation and maintenance. Additionally, compatibility with both your Operational Technology (OT) and Information Technology (IT) systems is crucial for leveraging the acquired data. Lastly, your chosen remote I/O solution should incorporate or support cybersecurity features to safeguard the diligently collected data. This section delves into a detailed exploration of these key considerations.

Avoid Compromising User-Friendliness

The flexibility provided by modular remote I/O devices may come with hidden expenses and additional complexity if due attention is not paid to the implementation and practical use of the device within your field application. Sacrificing usability for increased flexibility should be avoided, as it may result in expenditure of additional efforts that counteract the benefits of modularity. User-friendliness is a critical aspect that may present challenges in two primary stages.

Initial Setup

Modular I/O solutions are ideal for IIoT applications with diverse data acquisition requirements. In scenarios where modular I/O devices are necessary, a large number of I/O modules is likely needed. Given the numerous components to manage, it is vital to streamline the setup process. Look for installation features that are user-friendly, including convenient and standardized mounting options, as well as an optimized wiring design.

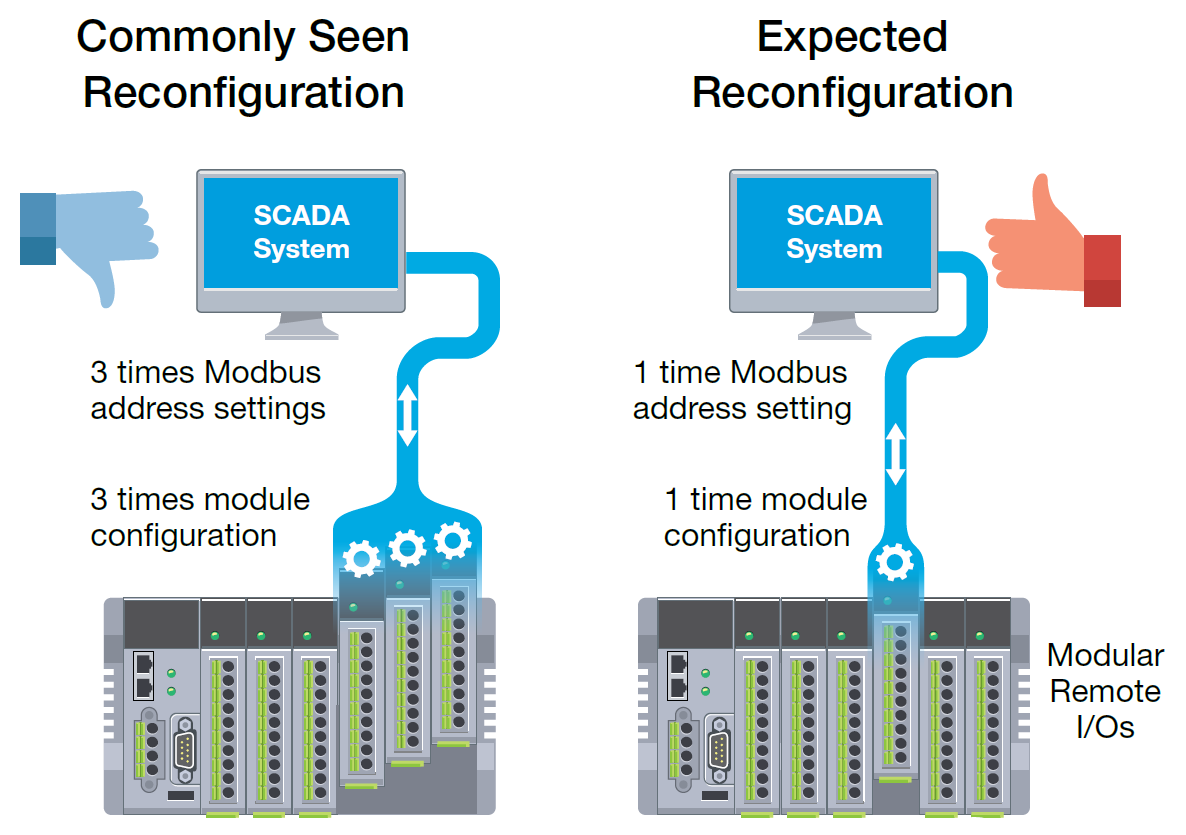

Operational Efficiency and Maintenance

Modular I/O devices are also crucial in adjusting and expanding the scale of data acquisition applications. However, a larger system demands more time to configure additional I/O modules. Changing a single module within the system necessitates reconfiguration of the unchanged modules due to the alteration in sequencing. Apart from modules, ensuring that all SCADA system configurations are up-to-date and compliant with every module change is imperative. A user-friendly modular I/O solution can effectively mitigate unnecessary efforts and should not be underestimated.

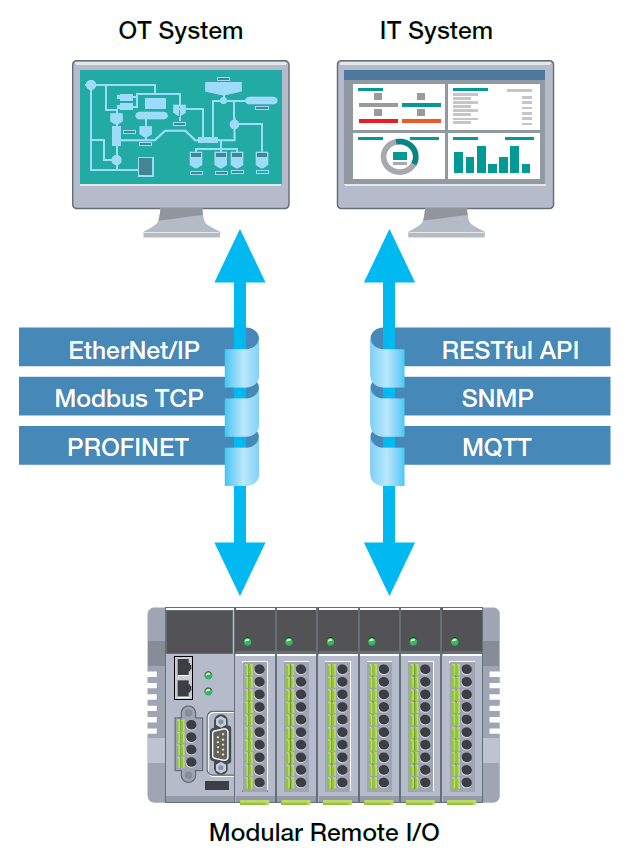

Recognize the Importance of I/O in IIoT

The integration of Information Technology (IT) and Operational Technology (OT) systems in modern IIoT applications has led to the development of enhanced edge devices, including modular I/O solutions. Despite this, OT and IT systems rely on distinct communication protocols. While a universal remote I/O solution for both IT and OT is unnecessary, ensuring seamless integration and operation of all components within your IIoT application is paramount. Emerging IT protocols such as MQTT, SNMPv3, and RESTful APIs can empower OT applications to utilize traditional IT-based analytical tools or services. Choosing a modular remote I/O that is future-proof with IT/OT compatibility is crucial in the era of IIoT.

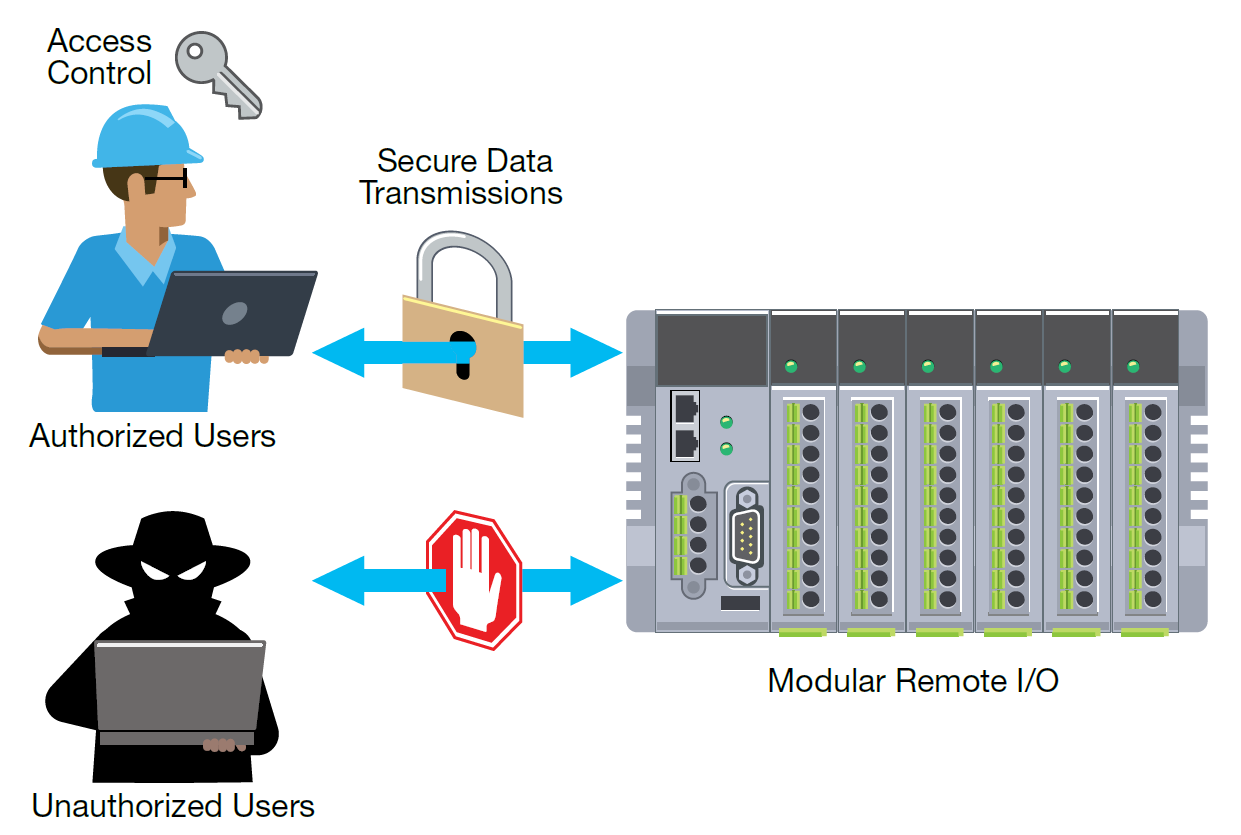

Prioritize Security

Given the interconnected nature of devices in any IIoT application, cybersecurity considerations are inevitable. Remote I/O devices are no exception to this. It is vital to manage the accessibility and data confidentiality of devices on your network diligently. Ensuring alignment between the security protocols enforced within your organization and equipping devices with essential security features is crucial. Devices should be capable of blocking unauthorized access and regulating permissible traffic flows. Additionally, employing secure data transmission methods for sensitive information exchanged over the network safeguards your valuable data. Cybersecurity should be a pivotal factor when selecting modular I/O solutions.

Adhering to these considerations while selecting your remote I/O solutions can simplify data collection processes and ensure the smooth and secure operation of your daily processes. In anticipation of evolving demands in I/O connectivity, Moxa has engineereda future-proof modular remote I/O device that enhances value delivery with reduced effort for IIoT data acquisition. For further insights into industrial connectivity, access ourE-book.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024