Automated storage and retrieval systems (AS/RSs) are increasingly utilizing wireless technology as an alternative to wiring, especially in challenging environments. A dependable wireless network plays a crucial role in ensuring the seamless operation of AS/RSs. A recent accomplishment in China serves as a great illustration of implementing resilient wireless networks in confined spaces with extreme temperatures.

Efficient Storage Optimization

AS/RSs are intelligent systems employed in warehouses, distribution centers, and manufacturing plants to streamline storage procedures and boost efficiency. These intelligent systems are typically employed in scenarios involving frequent movement of goods in and out of storage, tight storage capacity due to spatial limitations, and precise handling to prevent damages that could lead to substantial losses. AS/RSs usually feature an automated shuttle-storage-shelving layout that manages the movement of goods between shelves, minimizing the margin for human errors.

Adopting Industrial Wireless Technology

Wireless networks are gaining popularity in industrial settings due to their multiple advantages. The absence of extensive cabling requirements in wireless networks not only reduces costs but also eliminates the hassle of setting up long stretches of cables, particularly in large-scale networks. Deploying cables for industrial mobile equipment, such as AS/RS systems, is not only costly but also restricts the system’s mobility.

However, wireless networks in industrial environments may face interference that disrupts the wireless connections, causing system downtime. Establishing a reliable wireless network to minimize these disruptions presents significant benefits for industrial operators.

Case of Successful Implementation

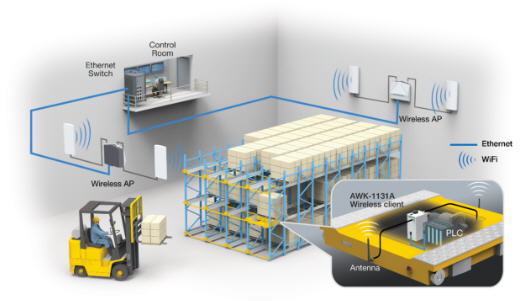

In a recent case, an AS/RS manufacturer in China assisted a food company in developing an intelligent storage warehouse for storing fresh food at extremely low temperatures. Early in the development stage, it became evident that installing cables would be overly complex and disruptive to their operations. Consequently, a dependable wireless network emerged as the preferable solution to facilitate communication between the control center and the numerous shuttle systems.

Due to limited available space on the shuttle systems, the wireless equipment needed to be compact yet resilient to ensure uninterrupted operations. Additionally, the warehouse setup required a wireless network capable of withstanding sub-zero temperatures and providing swift handover times to enable real-time control and monitoring of the shuttle systems. Additional system specifications included comprehensive wireless coverage on shuttle systems for consistent connectivity with the control center and an isolation design to shield the wireless devices from electrical interference induced by the shuttle system motors.

To guarantee optimal performance of the shuttle systems in this AS/RS, wireless devices must excel in three key areas: compact yet durable design, seamless roaming capability, and extended wireless coverage.

Moxa’s Cutting-edge Solutions

The sturdy, pocket-sized AWK-1131A is engineered to sustain wireless operations in harsh industrial environments, including cold-storage warehouses where temperatures can plummet to -40°C, while also fitting snugly within space-constrained shuttle systems. Furthermore, the AWK-1131A incorporates built-in power and RF-isolation to safeguard wireless devices from electrical interference generated by motors. These design elements save space and eliminate the need for additional isolator accessories.

Seamless roaming functionality is crucial for wireless devices. The AWK-1131A series supports client-based Turbo Roaming technology, delivering rapid handover times at the millisecond level to ensure continuous connectivity of client devices on the shuttle systems with access points (APs). This seamless connectivity enhances productivity by enabling smooth movement of the shuttle equipment between shelves.

Moreover, the AWK-1131A supports the 802.11n standard, offering a throughput rate of up to 300 Mbps and leveraging MIMO technology to optimize wireless availability in shuttle systems. Mounting an antenna on both the front and back of the shuttle system guarantees seamless connections with APs affixed to the wall. Additionally, the 5 GHz channel provides a low-traffic communication channel for wireless transmissions, preventing unwanted timeouts arising from channel saturation.

For more information, access our complete array of industrial wireless success stories.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024