The Controller Area Network (CAN) protocol, pioneered by Robert Bosch GmbH in the 1980s for automotive communication, has emerged as an essential element of numerous contemporary industrial networks. Initially crafted to streamline communication among electronic control units (ECUs) in vehicles, CANbus has transcended its automotive roots to enhance applications in diverse industrial sectors, particularly in renewable energy and industrial control systems. This piece delves into the pivotal characteristics that position CANbus as the favored option for industrial networking experts, showcasing its practical utility across diverse industrial scenarios.

Transitioning from Auto to Industrial Applications: A Smooth Shift

The triumph of CANbus in the automotive sector underscores its capacity to link systems with efficacy and dependability. These attributes seamlessly transfer to industrial automation, particularly in energy storage systems. Analogous to how CANbus orchestrates communication among varied control units in vehicles, it presently assumes a pivotal role in overseeing energy storage in renewable energy setups. These setups often encompass multiple battery units, inverters, and other components necessitating seamless communication to optimize energy generation, storage, and distribution. CANbus furnishes the sturdy and efficient communication infrastructure requisite for these complex systems to operate efficiently. While CANbus is a natural match for energy systems, its features also yield tangible benefits for a broad spectrum of other industrial applications.

Cardinal Attributes Driving CANbus Adoption

Industrial engineers have pinpointed several core attributes of the CANbus protocol that have accelerated its widespread adoption in various industrial applications. In the ensuing section, we shall delve into these key traits and how they generate tangible merits for diverse industries.

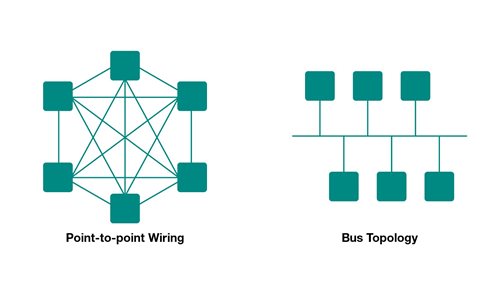

- Simplified Wiring

Within intricate industrial networks, traditional point-to-point wiring can prove burdensome. CANbus circumvents this hurdle with its two-wire bus and bus topology. By obviating the necessity for numerous individual connections, CANbus aids in curtailing cable clutter and simplifying installation intricacies, thereby culminating in more pliable and well-organized wiring architectures.

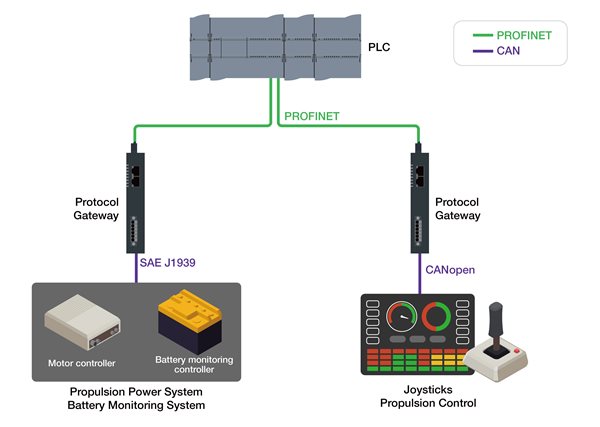

The boon of simplified wiring has garnered considerable attention in the marine industry, where CANbus gateways are being deployed to interlink onboard systems for propulsion and battery monitoring. Given the premium nature of space, employing compact gateways empowers marine vessel operators to leverage CANbus for reducing cabling and costs, while optimizing the limited onboard space.

- Resilient Communication

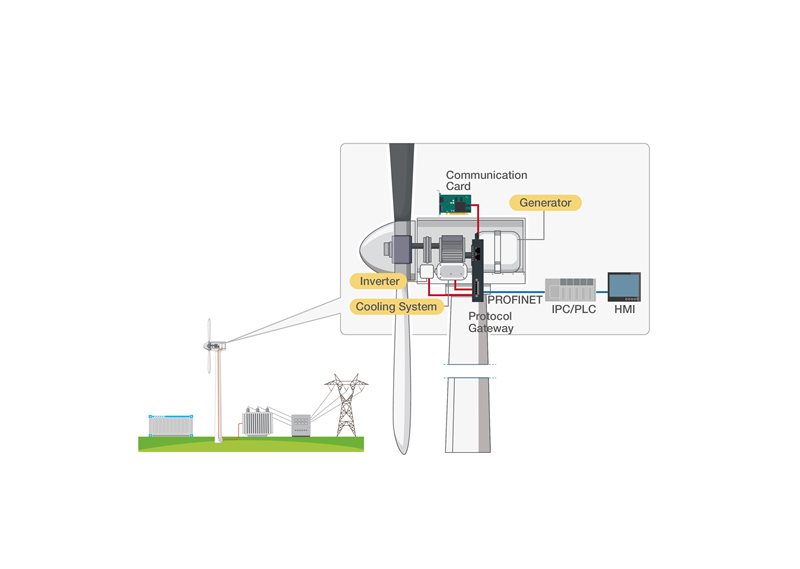

Industrial environments frequently pose challenging conditions characterized by extreme temperatures, vibrations, and electromagnetic interference. CANbus excels in such environments owing to its differential signaling and error detection mechanisms. Differential signaling ensures dependable data transmission even in the presence of electrical noise; concurrently, support for error detection, data acknowledgment, and re-transmission aids in ensuring data integrity.

These resilient attributes of CANbus play a pivotal role when harnessed in industrial applications abundant in electromagnetic interference, such as within wind turbine generators. By deploying protocol gateways, wind farm operators can interconnect turbine components using CANbus and transmit data across diverse protocols to a monitoring interface. The high resilience of CANbus guarantees that data transmissions remain unaffected by the electrical noise generated inside the turbine, thus ensuring that engineers consistently receive accurate data.

- Real-time Management

For time-sensitive industrial applications necessitating precise control, real-time control capabilities prove pivotal. Unlike conventional mainstream serial communication protocols, CANbus supports this functionality. CANbus prioritizes critical control commands to ensure they are invariably processed first. This prioritization occurs through message prioritization and arbitration, thereby guaranteeing that critical tasks receive the requisite bandwidth and remain uninterrupted.

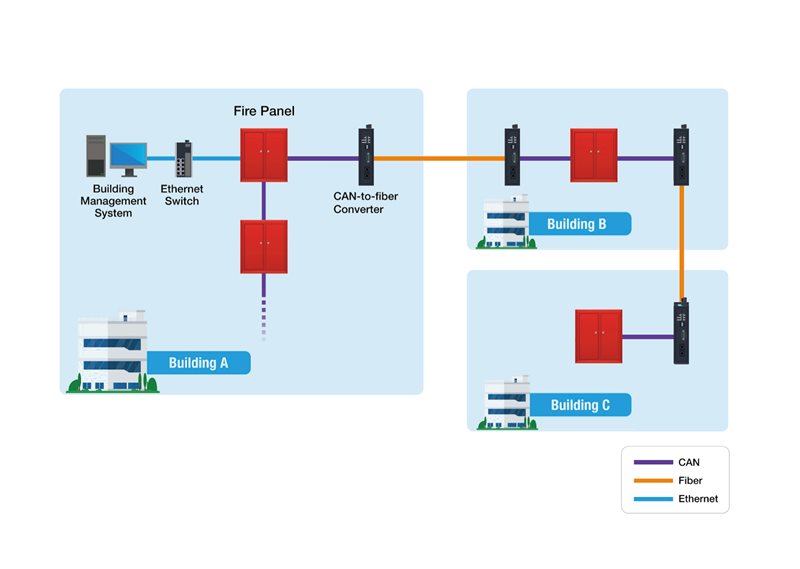

This capability to reliably process critical data renders CANbus the preferred protocol in scenarios necessitating precise synchronization and instantaneous responses, such as critical fire alarm systems. For these alarm systems to be effective, all components—including smoke detectors, alarm lights, and buzzers—must possess synchronized operation throughout the entire facility. By interlinking these components over CANbus, engineers can leverage its data prioritization capabilities to ensure all systems promptly respond in the event of an emergency. Furthermore, engineers can employ CAN-to-fiber converters to seamlessly extend the advantages of CANbus communication and link fire systems across diverse sites over extensive distances.

- Efficient Integration

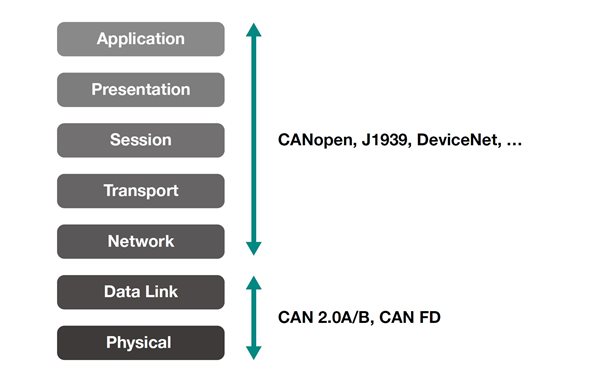

The CAN 2.0A/B and CAN FD standards lay down the foundational layers of communication. Tailored to specific needs, industries can define supplementary higher-layer protocols to furnish standardized frameworks for device profiles and communication entities. Some instances of high-level CANbus protocols encompass CANopen, J1939, and DeviceNet. These protocols communicate over the same CAN data layer standards, enhancing interoperability and streamlining the integration of diverse systems.

An exemplary demonstration of this adaptability in practice is the utilization of CANbus in medical equipment. By incorporating space-efficient CANbus interface cards into IPCs embedded in medical devices, the system builder can integrate varied medical systems such as patient monitors, blood pumps, and oxygen generators operating on diverse higher-layer protocols like CANopen or J1939.

Empowering Industrial Applications Through Versatility

CANbus has evolved into an indispensable asset for an array of industrial sectors, ranging from the automotive industry that conceived the technology to additional sectors like renewable energy and building automation. The amalgamation of simplified wiring, robust communication characteristics, and real-time control functionalities positions CANbus as a highly versatile instrument for industrial engineers. The capacity to tailor its usage through higher-layer protocols further augments its flexibility, enabling engineers to seamlessly integrate CANbus into a broad spectrum of applications. These traits render it an enticing choice for engineers seeking a cost-effective, reliable, scalable, and efficient means to link complex systems.

Whether you are optimizing energy storage systems, automating a production line, or integrating control systems, CANbus harbors significant potential to enhance efficiency and reliability across a diverse array of industrial applications.

Moxa Solutions

Moxa presents an extensive array of solutions to empower your industrial applications with the advantages of CANbus. Visit the microsite for further details regarding our comprehensive CANbus product lineup.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024