In former times, automated systems were relatively isolated and developed distinct specialized protocols such as Modbus, EtherNet/IP, and PROFINET. These protocols, referred to as industrial fieldbus protocols, offer particular advantages for various system application needs.

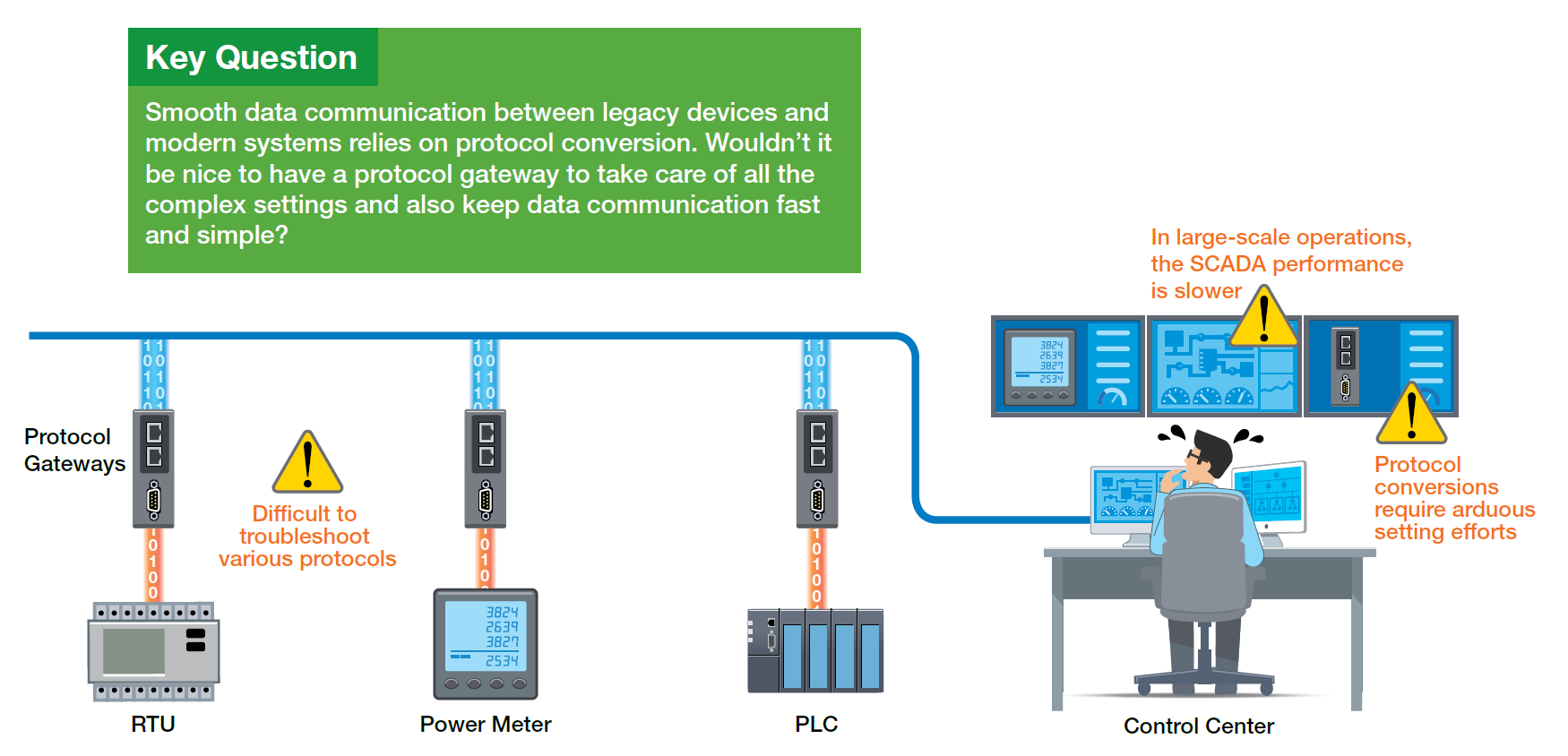

Presently, the shift towards interconnected factories has resulted in an increased need for protocol conversion due to two primary reasons. Firstly, dated devices typically utilize communication protocols based on serial connections, whereas contemporary SCADA systems, gaining popularity in industrial automation, depend on Ethernet communication. To facilitate seamless data exchange between older serial devices and SCADA systems, converting serial signals to Ethernet is essential. Secondly, a factory might possess multiple separate control systems. To enable effective system-to-system communication for improved operational efficiency and visibility, a method for translating data between systems is required.

Essential Factors to Consider When Selecting Protocol Gateways

Protocol gateways play a crucial role in ensuring smooth data transfer in a unified communication system. The following three considerations offer guidance to aid in choosing a protocol gateway that provides the utmost advantages. If your legacy serial devices use proprietary protocols instead of the industrial fieldbus protocols mentioned earlier, serial device servers can act as a simple link between your old serial devices and contemporary communication systems. Explore our article for insights on selecting the right serial device server.

Commence Strongly With Speedier Configuration

If configuring IP addresses and COM port settings manually for serial device servers seemed tedious, dealing with industrial protocol conversion settings will prove even more challenging. Industrial protocol conversion settings are intricate and involve various data formats. Even seasoned engineers may find themselves overwhelmed. Hence, a reliable protocol gateway should not only convert protocols but also simplify convoluted configurations for both upstream and downstream protocols. The gateway must accurately determine which data from which protocol needs conversion. A user-friendly graphical interface offering these functions on an intuitive screen can significantly expedite the configuration process. View our video to witness how seamless protocol conversions can be.

Ease the Burden of Resolving Issues

System downtime results in loss of time, productivity, and financial resources. Naturally, engineers aim to rectify issues promptly. However, troubleshooting can be challenging. When connecting multiple devices using diverse protocols, identifying the cause of communication problems becomes more complex as determining whether the issue lies at the Ethernet or serial end is necessary. Time and effort are often wasted trying to pinpoint the root cause of communication failures. Additionally, the absence of effective diagnostic tools to expedite identifying the root cause compounds the frustration. A proficient method is needed to identify the source of issues swiftly and restore system communication. Here is an example demonstrating how to promptly reestablish communication with your power meters.

Resolving protocol conversion issues necessitates the ability to examine the packets passing through the gateway. Nonetheless, troubleshooting capabilities and tools may be limited at times due to security protocols (e.g., restrictions on third-party utilities in adherence to IT policies) or platform limitations (e.g., inability to directly install utility tools on a PLC). Hence, a protocol gateway equipped with a practical utility tool or built-in troubleshooting features for promptly ascertaining connection status, timeout occurrences, and invalid response counts can be hugely beneficial. Remember to factor in the time and resources spent on troubleshooting when choosing your gateway solution.

Data Acquisition Performance is Vital

Balancing cost and performance can pose a significant challenge when requiring protocol conversion in a large-scale setting. When numerous devices necessitate protocol conversion and communication within a single SCADA system, ensuring the system’s performance meets expectations becomes crucial. While utilizing a one-port protocol gateway for each field device can ensure immediate data conversion and transmission, the costs could be high and maintenance efforts might overwhelm daily operations. Conversely, high-port density protocol gateways may offer a cost-effective solution with efficient deployment and straightforward management. However, concerns regarding performance may arise in data handling. Since most protocol communications are based on poll-and-response mechanisms, processing extensive data polls can strain gateways, leading to performance and response time issues in the SCADA system.

Design your network thoughtfully by combining one-port and high-port density protocol gateways. When opting for a high-port density protocol gateway, ensure its data polling mechanism aligns with your requirements.

A user-friendly protocol gateway can significantly enhance your system’s performance. Delve into the three key aspects mentioned above and choose your solution wisely. For instance, consider Moxa’s MGate protocol gateways that facilitate efficient protocol conversion to expedite your system’s operation with seamless data communication. If you wish to learn more about industrial connectivity, download our E-book.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024