Time-critical networking (TSN) stands as the subsequent phase in the development of typical Ethernet technologies to cater to the prospective necessities of the Industrial Internet of Things (IIoT). TSN empowers standard Ethernet networks to offer deterministic services and unify individual automation sectors that were previously separated by the myriad of purpose-built protocols from the past.

Interoperability – The Core Element for TSN’s Success

TSN technologies present a scalable and foreseeable strategy for deterministic networking over standard Ethernet. However, given that TSN is more of a toolkit rather than a unified comprehensive solution, integrators inevitably have to depend on autonomous vendors and various protocols to meet the particular requirements of each industrial application. This dilemma underscores the significance of interoperability in guaranteeing the triumph of TSN assimilation. In essence, a consolidated infrastructure built on TSN fundamentally necessitates interoperability on two vital fronts:

- Unified architecture that complies with TSN for Layer 2 networking and messaging

- Shared semantics for communication across multiple protocols

The Path Leading to IIoT and Industry 4.0

The Path Leading to IIoT and Industry 4.0

Shared Architecture: Layer 2 Interaction

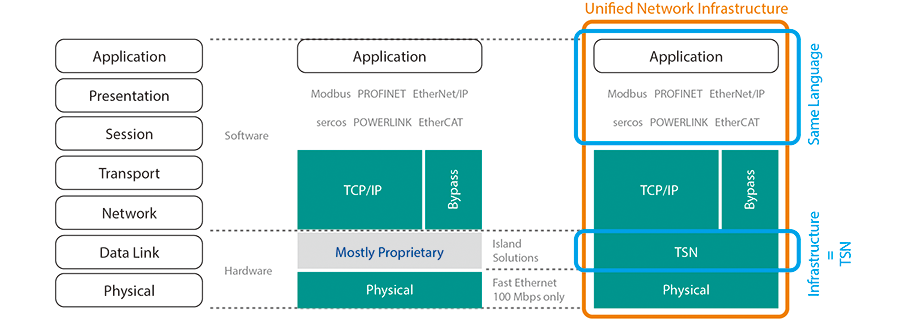

As a definite Ethernet standard, TSN essentially functions as a Layer 2 technology within the Open Systems Interconnection (OSI) model of computer networking. Also referred to as the Data Link Layer, Layer 2 encompasses technologies designed to relay Ethernet frames. In simple terms, TSN does not introduce a new technology; rather, it extends the functionality of IEEE 802.1—Ethernet. Ethernet can ensure real-time data transmission, yet it lacks the ability to ensure the precise arrival time of the data.

To meet the stipulations of Industry 4.0, which include definite communication over low-latency networks, resilience despite elevated network loads, and merging data delivery for both information technology (IT) and operational technology (OT), an IEEE task group formulated the open TSN standards.

By utilizing TSN-prepared Ethernet switches, integrators can satisfy the high-bandwidth real-time needs of Industry 4.0 without the need for alterations to their current application programs. Additionally, they can accomplish this and even integrate “plug-and-play” devices into merged networks by solely deploying standard IEEE Ethernet switches.

Shared Semantics: Protocol Interoperability Beyond Layer 2

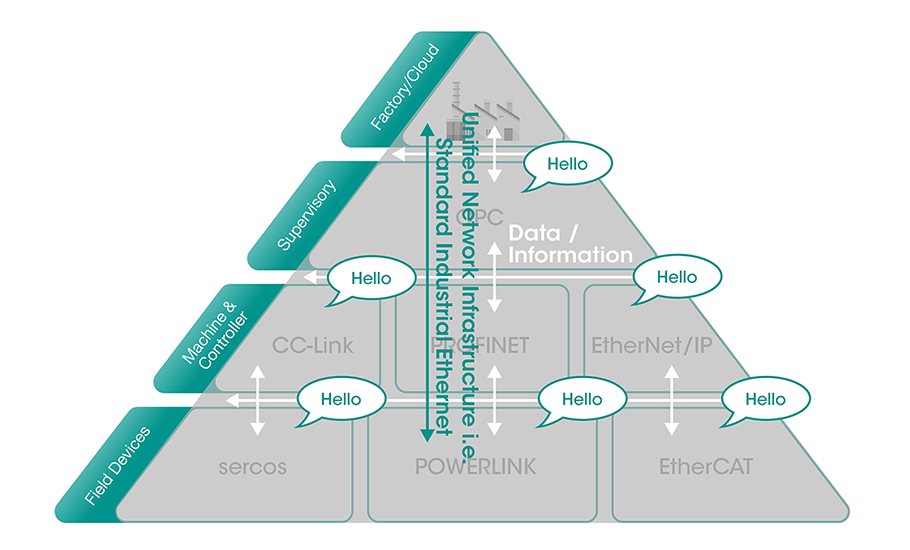

Although devices within the future autonomous pyramid can be produced by separate vendors, each device must possess the capability to communicate with every other constituent in the system—not solely Layer 2 devices—in order to unlock the full potential of the IIoT. Besides eliminating barriers that segregate traditional automation silos at the Layer 2 level, a successful implementation of TSN necessitates protocol interoperability across different layers to empower more adaptable topologies and unveil new prospects for industrial applications.

For instance, industry groups globally—including the CC-Link Partner Association (CLPA), EtherCAT Technology Group (ETG), Ethernet Powerlink Standardization Group (EPSG), Mechanical Engineering Industry Association (VDMA), Open DeviceNet Vendors Association (ODVA), and PROFIBUS & PROFINET International (PI), among others—converge around the OPC Unified Architecture (OPC UA) and associated specifications to establish shared semantics among various vendors and standards.

Complete Harmony for Industrial Automation

Complete Harmony for Industrial Automation

The Consolidated Base of Industrial Networking

As the IIoT mandates high-bandwidth, low-latency, deterministic networking to enable real-time communications for industrial control systems, TSN introduces standard Ethernet technologies that can furnish deterministic services, transcending traditional constraints of best-effort communications. Manufacturers are no longer constrained to segregated automation islands and control systems for their applications. Instead, industrial applications can anticipate an interconnected future with innovative bilateral communication channels that surpass the horizontal and vertical segments of the conventional Purdue model.

With international standard organizations and device vendors like Moxa rallying around TSN, it is evident that these standard Ethernet technologies will emerge as the future cornerstone of industrial networking.

For further details, kindly access our white paper.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024