In the sphere of industry, information holds immense value. The rapid drive across industries to gather and scrutinize vast quantities of raw data is molding the Industrial Internet of Things (IIoT) as we comprehend it in this day and age. A domain where the broad impact of the IIoT is keenly observed is in the accumulation of I/O data from devices in the field. Increasingly, the IIoT necessitates networks to transmit gathered I/O data to OT (private cloud) and IT (public cloud) platforms for analytical purposes. Typically, modular remote I/Os are employed to fetch I/O data. Regrettably, they come with a few challenges that not only vex engineers but also affect day-to-day operations. In this article, we delve into these challenges and present a solution that will resonate with both OT and IT personnel alike.

The Harsh Reality of Reconfiguration

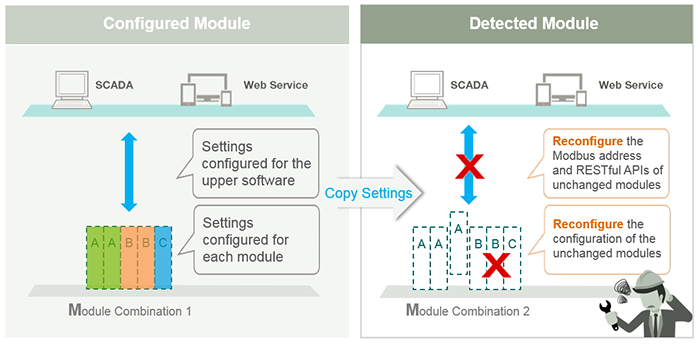

With modular remote I/O setups, one of the major hurdles is replicating configuration settings to the current modules with varying module assortments. Following the addition, relocation, or removal of a module, the configuration of the unchanged modules, encompassing the Modbus address and RESTful APIs to the upper software, must be redone. System integrators ideally desire to retain all completed settings between devices and upper software and only configure the newly added modules with minimal effort.

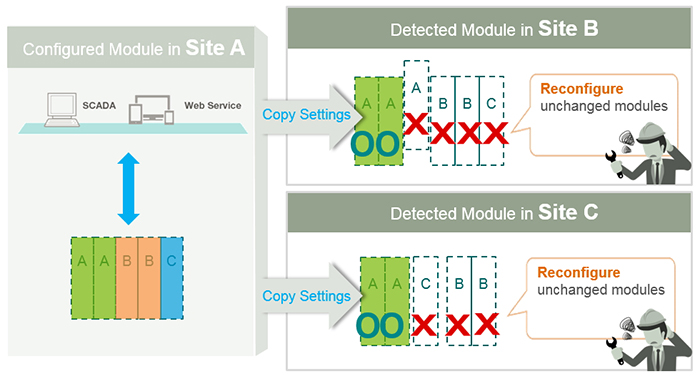

However, the reality for system integrators entails enduring lengthy hours and repetitive reconfigurations when tackling different module permutations at various sites. For instance, assume that the module arrangements in Site A, Site B, and Site C are AABBC, AAABBC, and AACBB, respectively. Duplicating the configuration settings of the I/O modules in Site A to those in Sites B and C is not a straightforward task. In Site B, an additional module (indicated by A in the diagram) has been introduced. Consequently, the SI not only has to configure the newly added module but also has to reconfigure modules B, B, and C. The same exasperating scenario is mirrored in Site C where a module has been replaced by another (denoted as C). Here, module C needs to be configured from the ground up, and the two modules labelled as B have to be reconfigured. The act of adding, deleting, or relocating a single module brings about a significant amount of additional effort—an ordeal that system integrators find frustrating. Hence, eradicating the need for reconfiguration in replicating configuration settings will result in considerable time and cost savings.

The Importance of Appropriate Protocols

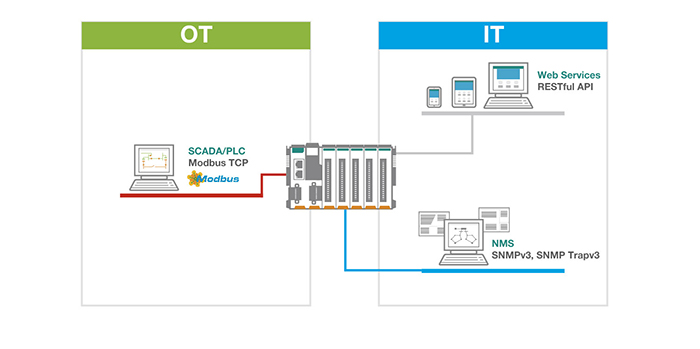

When it comes to protocol compatibility, modular remote I/Os can be a source of frustration. Numerous modular remote I/Os available in the market do not offer support for IT protocols like SNMP and RESTful, which many engineers are accustomed to. Consequently, engineers are compelled to spend more time and effort to culminate their projects as the modular remote I/Os solely support OT protocols. Acquiring a solution that sustains numerous IT and OT protocols within a single device can make a profound impact.

Moxa’s Resolutions

Our ioThinx 4510 is crafted with an instinctive web configuration tool that endorses unique names for modules/channels. Put bluntly, the configuration settings, including the Modbus address/RESTful channel name to SCADA, will automatically correspond with the particular module. No additional reconfiguration efforts are needed regardless of whether you modify the module sequence, add, or remove a module. You simply have to configure the newly added module.

Furthermore, the ioThinx 4510 supports a variety of protocols, such as Modbus TCP for OT engineers, along with SNMP and RESTful API for IT engineers. The ioThinx 4510 fetches I/O data and transforms the data into any of these protocols, enabling effortless connectivity for your applications.

For further details, please visit our microsite.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024