As the utilization of electrical equipment in industrial settings continues to grow, safeguarding these vital systems becomes increasingly important. Unforeseen power failures not only result in heightened maintenance expenses for your electrical apparatus but also reduce operational efficiency, productivity, and overall business earnings. To guarantee a consistent power supply, it is essential to monitor the power quality in your application to shield your electrical machinery from unwanted disruptions and harmful fluctuations.

When formulating a comprehensive power quality monitoring strategy, two crucial pieces of equipment to focus on are switchgears and uninterruptible power supplies (UPSs). In essence, switchgears serve as the initial checkpoint for the transmission of utility power into your factories and data centers. These devices alter voltage levels, oversee power currents, and shield your industrial machinery from irregular fluctuations in electricity. Consequently, continuous monitoring of the condition of circuit breakers, surge protectors, current transformers, and power quality meters housed within your switchgears is imperative. Additionally, UPSs are utilized for supplying continuous power when the primary power source malfunctions and your backup power, such as a generator, is not readily available.

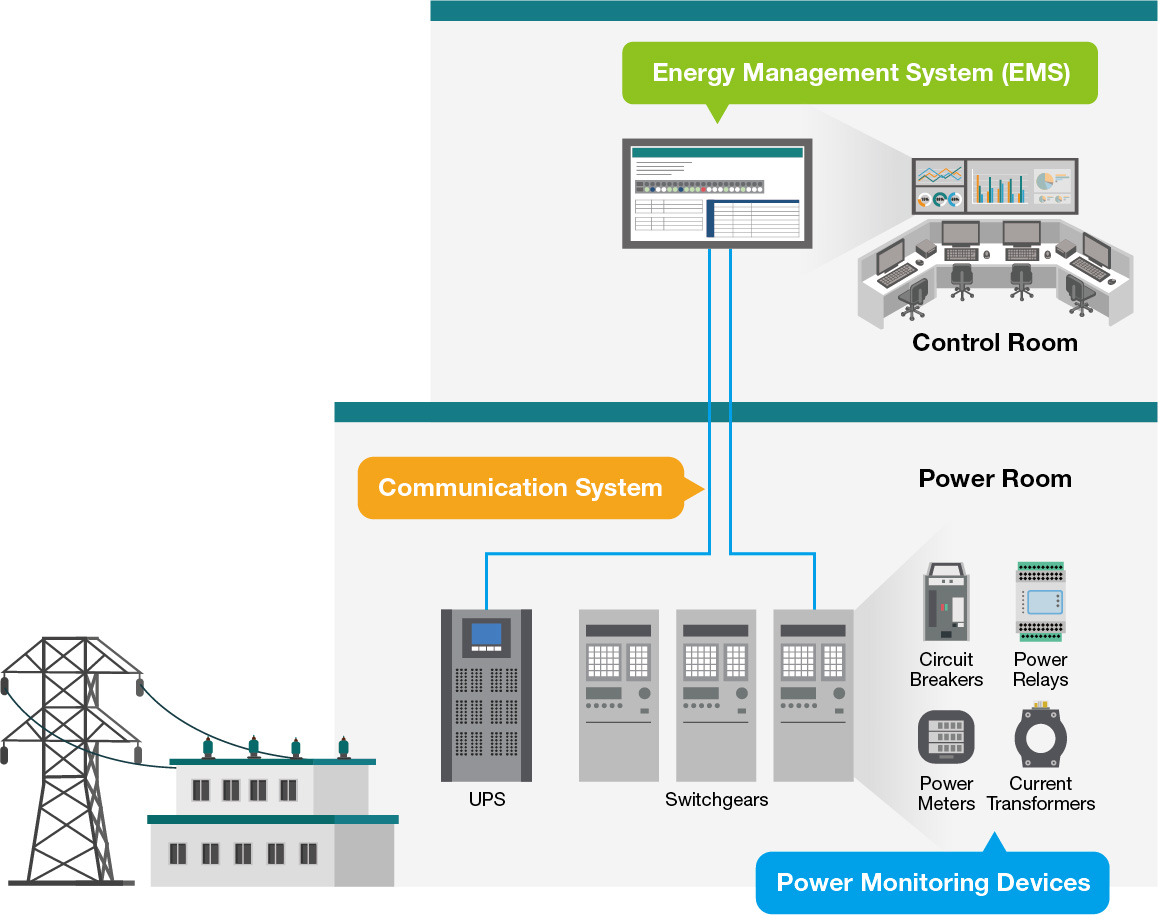

For real-time monitoring of your application’s power quality, it is crucial for switchgears and UPSs to link with an energy management system (EMS) so that operators can swiftly make decisions to minimize system downtime. Establishing a dependable communication network between these entities allows you to oversee power quality and react promptly to emergencies. Below are three recommendations to consider when building communication systems for power quality monitoring applications.

Initially, ensure that your communication system can withstand high levels of EMI. Just like your electrical equipment, communication systems for power quality monitoring must be safeguarded to ensure operators can access real-time power quality status updates. Since your communication devices are typically situated close to power systems that emit substantial EMI, which can easily disrupt network communications.

To reduce these disruptions, utilize a reliable solution with EMI immunity. Fiber cables offer excellent EMI resistance over extended distances and are an optimal choice for transmitting data from power equipment to the control center. Additionally, your connectivity devices should incorporate supplementary protection features like dual-power and dual-port inputs to ensure uninterrupted operation in case of a power source or port failure.

Secondly, your communication system should facilitate rapid recovery to minimize downtime. Connected devices for power quality monitoring usually rely on serial-based connections and industrial protocols like Modbus RTU. Meanwhile, EMSs typically use Ethernet-based OT/IT protocols such as Modbus TCP, SNMPv3, and BACnet/IP. A protocol gateway is typically necessary to enable communication between these devices and systems employing diverse communication protocols.

When communication errors occur, operators may not promptly receive power quality updates, making it challenging to detect abnormalities for timely responses. Furthermore, engineers may struggle to conduct root cause analysis due to insufficient information and the increased complexity of troubleshooting across different protocols. When selecting a protocol gateway for your communication system, ensure it includes diagnostic tools to swiftly pinpoint the root cause of an issue and expedite the restoration of your system.

Lastly, strategically plan your communication network to efficiently and securely access your power data online. An array of sensors related to power stability are accessible. When designing a power quality monitoring application, you must gather not only power-related data but also environmental information to maintain a stable power supply free from environmental disruptions. Both power and environmental sensors are available in various interfaces, so opt for connectivity solutions that are simple to install and upkeep in a limited-space cabinet.

Your network strategy should also encompass connectivity security. Connecting your switchgears and UPSs via public networks may expose your systems to potential vulnerabilities. Therefore, ensure your networking devices are fortified to prevent exploitation by hackers.

As a renowned specialist in industrial connectivity, Moxa has aided clients in implementing seamless, reliable, and secure communication systems for power quality monitoring applications. Browse through our case studies to explore how other enterprises have crafted communication systems for their switchgears and UPSs using Moxa solutions.

Require assistance in selecting connectivity or networking products for your project? Obtain our E-book and acquaint yourself with the key considerations for choosing the most suitable products for your requirements.

- Not Only for Automobiles: Discovering CANbus Technology in Various Industrial Settings - October 29, 2024

- Boost Your Network Performance: An Exciting Manual to PoE Switches! - September 10, 2024

- Understanding Gigabit Switches: Industrial vs Regular Gigabit - September 4, 2024